ຮັບສ່ວນຫຼຸດພິເສດຕາມປະລິມານ, ອັບເດດລາຄາຂາຍສົ່ງ ແລະ ການແຈ້ງເຕືອນສິນຄ້າໃໝ່ສົ່ງກົງເຖິງອິນບັອກຂອງທ່ານ.

ໂດຍການສະໝັກສະມາຊິກ, ທ່ານຍອມຮັບ ເງື່ອນໄຂການໃຫ້ບໍລິການ ແລະ ນະໂຍບາຍຄວາມເປັນສ່ວນຕົວ ຂອງພວກເຮົາ.

ເຂົ້າເຖິງຜູ້ຊ່ຽວຊານທີ່ໄດ້ຮັບການຢັ້ງຢືນຂອງພວກເຮົາໂດຍກົງ

ຮັບສ່ວນຫຼຸດພິເສດຕາມປະລິມານ, ອັບເດດລາຄາຂາຍສົ່ງ ແລະ ການແຈ້ງເຕືອນສິນຄ້າໃໝ່ສົ່ງກົງເຖິງອິນບັອກຂອງທ່ານ.

ໂດຍການສະໝັກສະມາຊິກ, ທ່ານຍອມຮັບ ເງື່ອນໄຂການໃຫ້ບໍລິການ ແລະ ນະໂຍບາຍຄວາມເປັນສ່ວນຕົວ ຂອງພວກເຮົາ.

ເຂົ້າເຖິງຜູ້ຊ່ຽວຊານທີ່ໄດ້ຮັບການຢັ້ງຢືນຂອງພວກເຮົາໂດຍກົງ

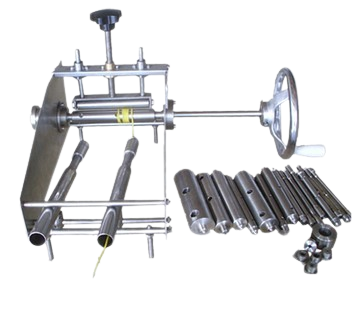

Overall diameter of the test piece: Φ2.5mm~Φ12.5mm

Diameter of mandrel: Φ4.0mm~Φ46mm (totally 14 pieces)

Tube sleeve: Φ3.5mm*2, Φ6mm*2, Φ10mm*2, Φ12mm*2, Φ16mm*2

Number of turns: 2~10 turns

Rotate speed: 1r/5s

Working station: 2

Material: SUS304 stainless steel

Working temperature: -15℃±1℃

Overall diameter (d) of test piece (mm) | Number of turns

d≤2.5 | 10

2.5<d≤4.5 | 6

4.5<d≤6.5 | 4

6.5<d≤8.5 | 3

8.5<d | 2

The cold bend test apparatus is designed according to IEC60811-1-4 clause 8.1 and figure 1, IEC60884-1, VDE0472, GB2951.4 and GB2099-94. It is applied to the test the cores of circular cross-section having an external diameter up to and including 12.5mm, sector shaped cores when it is not possible to prepare dumb-bells, and cables with an overall diameter up to and including 12.5mm or flat cables with a major axis dimension up to and including 20mm. The apparatus is consisted by one revolving mandrel and guiding device, and it shall be held in a suitable low temperature cabinet before and during the test.