SCHMIDT

ຂໍ້ມູນຜູ້ຜະລິດ

SCHMIDT – Mechanical Measurement Equipment for Production Lines and Testing Laboratories

Overview of SCHMIDT and Its Field of Activity

SCHMIDT is a manufacturer of mechanical measurement equipment, focusing on force, tension, torque, and parameters related to motion and material properties. The company’s instruments are developed for use in industrial production environments, technical laboratories, and quality inspection processes, where stable and repeatable measurement results are required.

Product development at SCHMIDT is closely aligned with the need for direct measurement during manufacturing and inspection, supporting the monitoring and control of mechanical parameters that influence material and product quality.

Measurement Approach in Production and Technical Inspection

SCHMIDT equipment is designed to perform mechanical measurements under real operating conditions. Measurements can be carried out directly on raw materials, semi-finished products, or finished components, allowing technicians to evaluate mechanical conditions at each production stage.

This approach enables measurement activities to be integrated into the operational process rather than being limited to final inspection. As a result, deviations in force, tension, or motion can be detected at an early stage, helping to reduce waste and improve process stability.

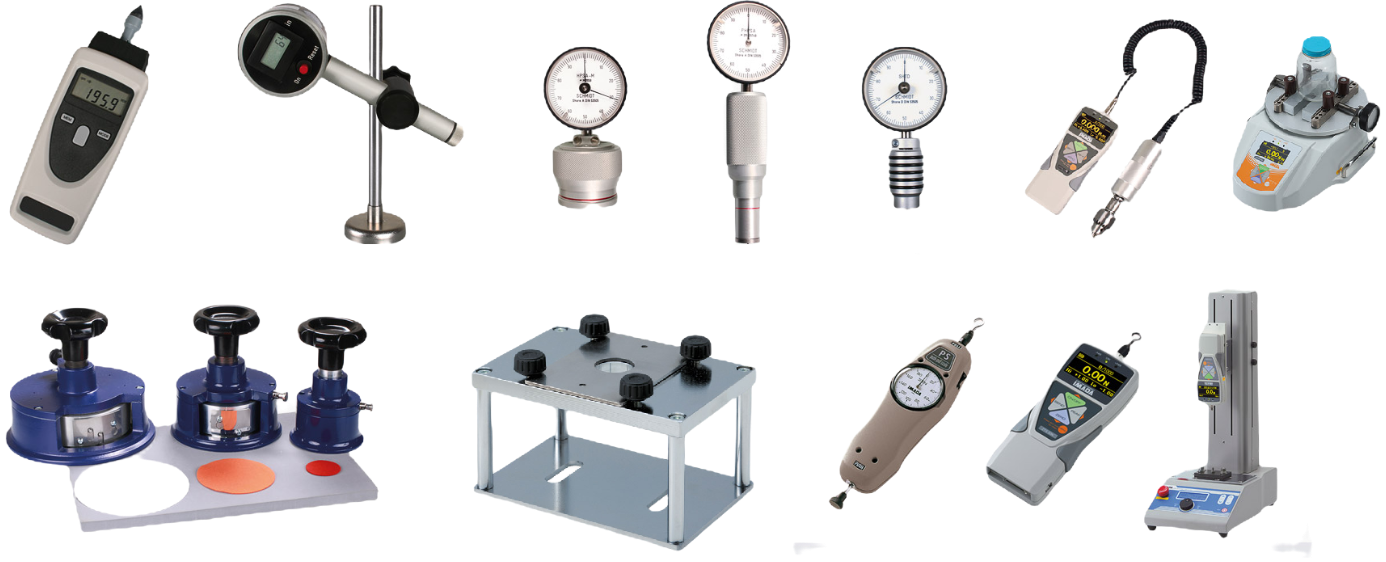

Mechanical Measurement Equipment Groups of SCHMIDT

SCHMIDT’s product portfolio is structured according to measurement functions, matching technical requirements in production and quality inspection.

Material Tension Measurement Equipment: Used to measure the tension of fibers, wires, belts, cables, and other elongated materials, supporting stability control during processing and manufacturing.

Force Measurement Equipment for Tension and Compression: Designed to measure applied forces on components, parts, and finished products through tension and compression tests, supporting mechanical property evaluation and quality inspection.

Torque Measurement Equipment: Used to measure and verify torque on shafts, motors, and rotating mechanical assemblies, supporting assessment of operational performance and mechanical stability.

Speed, Rotation, and Length Measurement Equipment: Designed to measure speed, rotational count, and length of moving materials or components in production lines, supporting motion monitoring and control.

Material Thickness Measurement Equipment: Used to measure the thickness of sheets, films, strips, and other thin materials, supporting geometric inspection and uniformity control.

Material Hardness Measurement Equipment: Designed to measure hardness of elastomeric and technical materials, supporting evaluation of mechanical properties and material quality.

Grammage Measurement Equipment: Used to measure weight per unit area of paper, board, films, and sheet materials, supporting material weight control in production and quality inspection.

Application in Quality Inspection and Process Control

SCHMIDT measurement equipment is used to monitor mechanical parameters that directly affect material and product quality. The measurement data supports technicians in process control, deviation detection, and maintaining stability in both production and quality inspection.

In modern manufacturing environments, where high accuracy and repeatability are required, measuring and controlling force, tension, and motion has become an essential part of technical workflows.

Conclusion

SCHMIDT provides mechanical measurement equipment for force, tension, torque, speed, and material property testing. Its product portfolio is organized by measurement function, making it suitable for use in production lines, testing laboratories, and industrial quality inspection processes.

ຮັບສ່ວນຫຼຸດພິເສດຕາມປະລິມານ, ອັບເດດລາຄາຂາຍສົ່ງ ແລະ ການແຈ້ງເຕືອນສິນຄ້າໃໝ່ສົ່ງກົງເຖິງອິນບັອກຂອງທ່ານ.

ໂດຍການສະໝັກສະມາຊິກ, ທ່ານຍອມຮັບ ເງື່ອນໄຂການໃຫ້ບໍລິການ ແລະ ນະໂຍບາຍຄວາມເປັນສ່ວນຕົວ ຂອງພວກເຮົາ.

ເຂົ້າເຖິງຜູ້ຊ່ຽວຊານທີ່ໄດ້ຮັບການຢັ້ງຢືນຂອງພວກເຮົາໂດຍກົງ