Partnering with businesses to optimize performance and save energy starting in early 2026

Energy costs are becoming a tightly controlled factor in manufacturing operations. An inefficient motor system can increase power consumption, generate excessive heat, and reduce equipment lifespan. Regular inspections help detect losses, phase imbalances, voltage drops, or insulation leaks early, before problems occur.

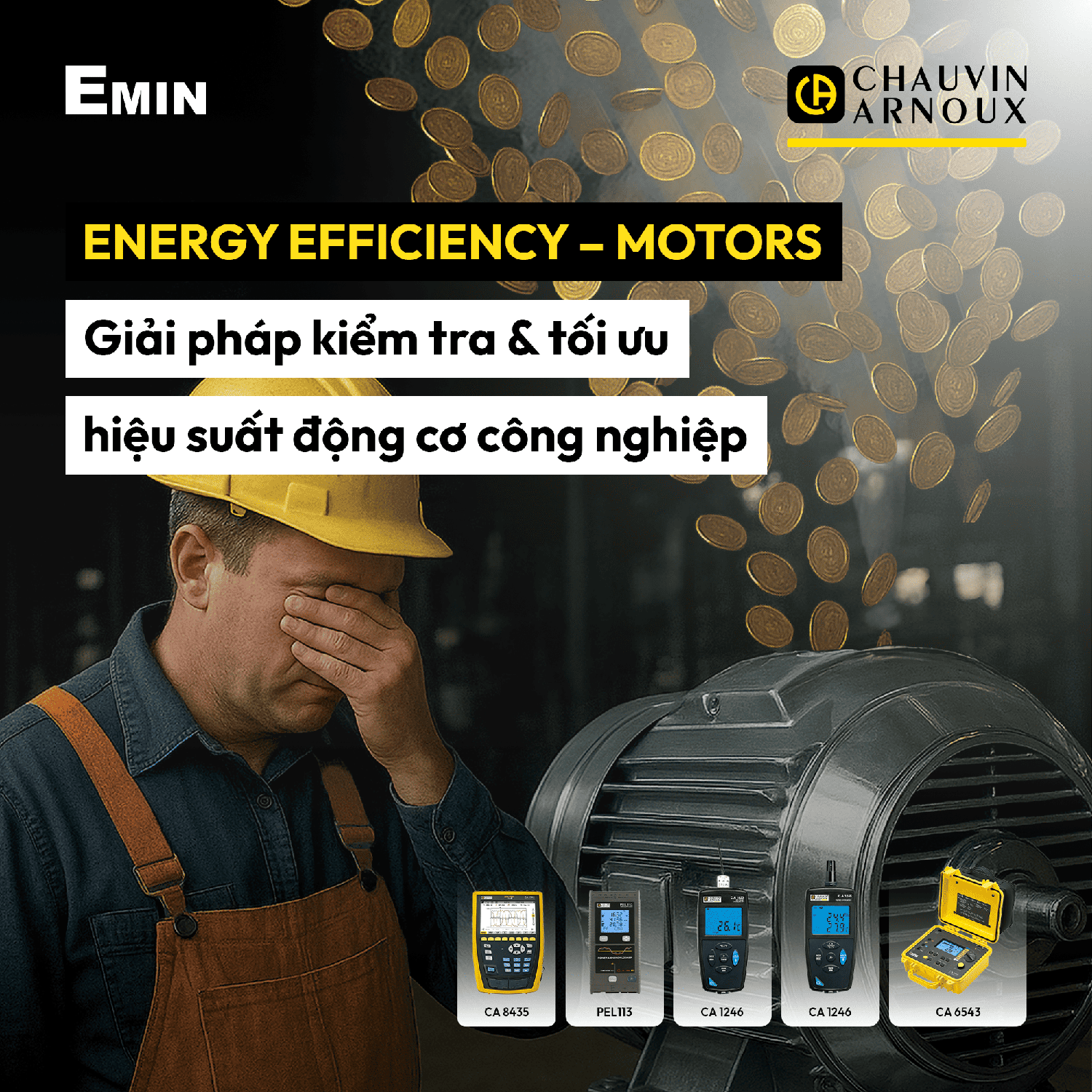

Voltage, current, and harmonic analysis using CA 8345

The quality of the power supply directly affects the performance and durability of the motor. Unbalanced voltage, waveform distortion, or low power factor all increase losses and generate heat.

The Chauvin Arnoux CA 8345 power quality analyzer allows for the comprehensive recording of three-phase parameters including voltage, current, power, power factor, and harmonics. The device supports real-time data logging and detailed report generation, helping engineers accurately identify the causes of energy loss or abnormal motor vibrations. The measured data not only aids in troubleshooting but also serves as a basis for evaluating the effectiveness of power system improvements after optimization.

Record actual power consumption with PEL113

Motors in factories typically operate under varying load cycles. Electricity consumption during peak production hours differs significantly from that during off-load periods.

The Chauvin Arnoux PEL113 data logger and power meter, combined with the MA194-350 series module, allows for continuous monitoring of energy consumption over several days. Active power, reactive power, and power factor are fully stored for trend analysis.

The real-world data helps businesses identify the most energy-consuming motor groups and develop optimal plans with clear priorities.

CA 6543 tests insulation resistance, reducing the risk of motor failure

Insulation degradation is a common cause of short circuits and sudden machine shutdowns. Environmental factors, dust, and material aging all affect the insulation resistance of windings.

The Chauvin Arnoux CA 6543insulation resistance tester allows testing at various voltage levels, supporting the assessment of degradation trends over time. Measurement results enable maintenance departments to proactively plan maintenance before problems occur. Regular insulation testing provides greater long-term value than addressing issues after the motor has already failed.

CA 1823 and CA 1246 are used for monitoring thermal and environmental conditions

High temperatures reduce the efficiency and shorten the lifespan of bearings and windings. Measuring surface temperature with the Chauvin Arnoux CA 1823 device helps to detect hot spots in bearings or motor housings early.

In addition, environmental conditions such as humidity and dew point directly affect insulation and heat dissipation. The Chauvin Arnoux CA 1246 temperature, humidity, and dew point meter provides the necessary data to assess the installation environment and develop appropriate control solutions.

Solutions tailored to each factory model

Motor performance doesn't depend on a single measurement. Power quality, power consumption, insulation condition, and operating temperature need to be monitored in parallel for a complete picture.

EMIN now offers a full range of Chauvin Arnoux equipment for testing and evaluating industrial motor systems. Our technical team provides consulting support to help select the most suitable solution based on factory size and specific optimization goals, enabling businesses to clearly control energy costs and achieve more stable long-term operation.