Get exclusive volume discounts, bulk pricing updates, and new product alerts delivered directly to your inbox.

By subscribing, you agree to our Terms of Service and Privacy Policy.

Direct access to our certified experts

Get exclusive volume discounts, bulk pricing updates, and new product alerts delivered directly to your inbox.

By subscribing, you agree to our Terms of Service and Privacy Policy.

Direct access to our certified experts

Hardness scale: HL, HB, HRB, HRC, HRA, HV, HS

Memory: 48~600 groups (impact times: 32~1)

Measuring range: HLD(170~960) See below table 1 and table 2

Accuracy: ±6HLD (760±30HLD) error of displayed value

repeatability of displayed value: 6HLD (760±30HLD)

Standard Impact Device: D

Optional Impact Devices: DC/D+15/G/C/DL

Max. Workpiece Hardness: 996HV (For Impact Devices D/DC/DL/D+15/C)

646HB(For Impact Device G)

Min. Radius of Workpiece (convex/concave) Rmin = 50mm (with special support ring Rmin= 10mm)

Min. Workpiece weight: 2~5kg on stable support

0.05~2kg with compact coupling

Min. Workpiece thickness: 5mm (Impact Devices D/DC/DL/D+15)

1mm (Impact Device C)

10mm (Impact Device G)

Min. thickness of hardened surface: 0.8mm

Power: Rechargeable Li lon battery 3.7V/600mA, 4 years life time

Continuous Working time: approx. 100 h (no back light off)

Charging time: 2-3.5 h

Operating temperature: 0~40 oC

Relative humidity: ≤90%

Overall dimensions: 152×84×34mm (main unit)

Weight: 0.3kg (main unit)

Standard delivery of portable leeb hardness tester RHL10

●Main unit

●Impact Device type D

●Test block with HLD value

●Charger

●Nylon brush

●Small supporting ring

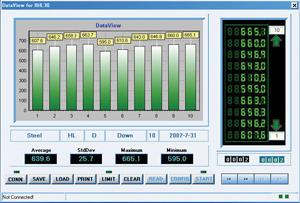

●DataView Software

●USB Communication cable

●Calibration Certificate

●Instruction manual

●Warranty card

●Carrying case

|

Material

|

Hardness method

|

Impact device

|

|||||

|

D/DC

|

D+15

|

C

|

G

|

E

|

DL

|

||

|

Steel and cast steel

|

HRC

|

17.9~68.5

|

19.3~67.9

|

20.0~69.5

|

|

22.4~70.7

|

20.6~68.2

|

|

HRB

|

59.6~99.6

|

|

|

47.7~99.9

|

|

37.0~99.9

|

|

|

HRA

|

59.1~85.8

|

|

|

|

61.7~88.0

|

|

|

|

HB

|

127~651

|

80~638

|

80~683

|

90~646

|

83~663

|

81~646

|

|

|

HV

|

83~976

|

80~937

|

80~996

|

|

84~1042

|

80~950

|

|

|

HS

|

32.2~99.5

|

33.3~99.3

|

31.8~102.1

|

|

35.8~102.6

|

30.6~96.8

|

|

|

Hammered steel

|

HB

|

143~650

|

|

|

|

|

|

|

Cold work tool steel

|

HRC

|

20.4~67.1

|

19.8~68.2

|

20.7~68.2

|

|

22.6~70.2

|

|

|

HV

|

80~898

|

80~935

|

100~941

|

|

82~1009

|

|

|

|

Stainless steel

|

HRB

|

46.5~101.7

|

|

|

|

|

|

|

HB

|

85~655

|

|

|

|

|

|

|

|

HV

|

85~802

|

|

|

|

|

|

|

|

Gray cast iron

|

HRC

|

|

|

|

|

|

|

|

HB

|

93~334

|

|

|

92~326

|

|

|

|

|

HV

|

|

|

|

|

|

|

|

|

Nodular cast iron

|

HRC

|

|

|

|

|

|

|

|

HB

|

131~387

|

|

|

127~364

|

|

|

|

|

HV

|

|

|

|

|

|

|

|

|

Cast aluminum

alloys

|

HB

|

19~164

|

|

23~210

|

32~168

|

|

|

|

HRB

|

23.8~84.6

|

|

22.7~85.0

|

23.8~85.5

|

|

|

|

|

Brass(copper-zinc alloys)

|

HB

|

40~173

|

|

|

|

|

|

|

HRB

|

13.5~95.3

|

|

|

|

|

|

|

|

Bronze (copper-aluminum/copper-tin alloys)

|

HB

|

60~290

|

|

|

|

|

|

|

Wrought copper

alloys

|

HB

|

45~315

|

|

|

|

|

|

|

No.

|

Material

|

HLD

|

Strength σb(Mpa)

|

|

1

|

Mild steel

|

350~522

|

374~780

|

|

2

|

High-carbon steel

|

500~710

|

737~1670

|

|

3

|

Cr steel

|

500~730

|

707~1829

|

|

4

|

Cr-V steel

|

500~750

|

704~1980

|

|

5

|

Cr-Ni steel

|

500~750

|

763~2007

|

|

6

|

Cr-Mo steel

|

500~738

|

721~1875

|

|

7

|

Cr-Ni-Mo steel

|

540~738

|

844~1933

|

|

8

|

Cr-Mn-Si steel

|

500~750

|

755~1993

|

|

9

|

Super strength steel

|

630~800

|

1180~2652

|

|

10

|

Stainless steel

|

500~710

|

703~1676

|

PC Software sample