Get exclusive volume discounts, bulk pricing updates, and new product alerts delivered directly to your inbox.

By subscribing, you agree to our Terms of Service and Privacy Policy.

Direct access to our certified experts

Get exclusive volume discounts, bulk pricing updates, and new product alerts delivered directly to your inbox.

By subscribing, you agree to our Terms of Service and Privacy Policy.

Direct access to our certified experts

- Basic Parameters

Screen Frame Size: 520(X)×420(Y)—737(X)×737(Y) (mm); Thickness:20-40mm

Min PCB(mm): 50(X)×50(Y) (mm)

Max PCB(mm): 400(X)×310(Y) (mm)

Thickness: 0.2mm~6mm(Use jig when pcb less than 0.4mm)

Curve: <1%(Diagonal measurement)

PCB Backside Part Height: 10mm

Conveyor Height: 900±40mm

Support: Magnetic support, Magnetic piece, Vacuum chamber(Option)

Clamp: Side clamp(Standard),please read the to option table

Edge Distance: PCB process edge ≥2.5mm

Conveyor Speed: 0~1500mm/s,increment 1mm

Conveyor Belt: U type sync belt

Stopper method: Air Cylinder

Stopper position: Set the PCB stopper position according to the size of board

Flow direction: L-R、R-L、L-L、R-R depends on customer

- Print System

Print Speed: 5-200mm/s adjustable

Print Head: Step motor drive scraper lifting

Scraper: Steel scraper,rubber scraper(option)

Scraper Angle: 60°

Scraper Pressure: 0~20kg

- Vision System

Substrate Separation: Three-section Substrate Separation speed:0.1-20mm/s distance:0-20mm

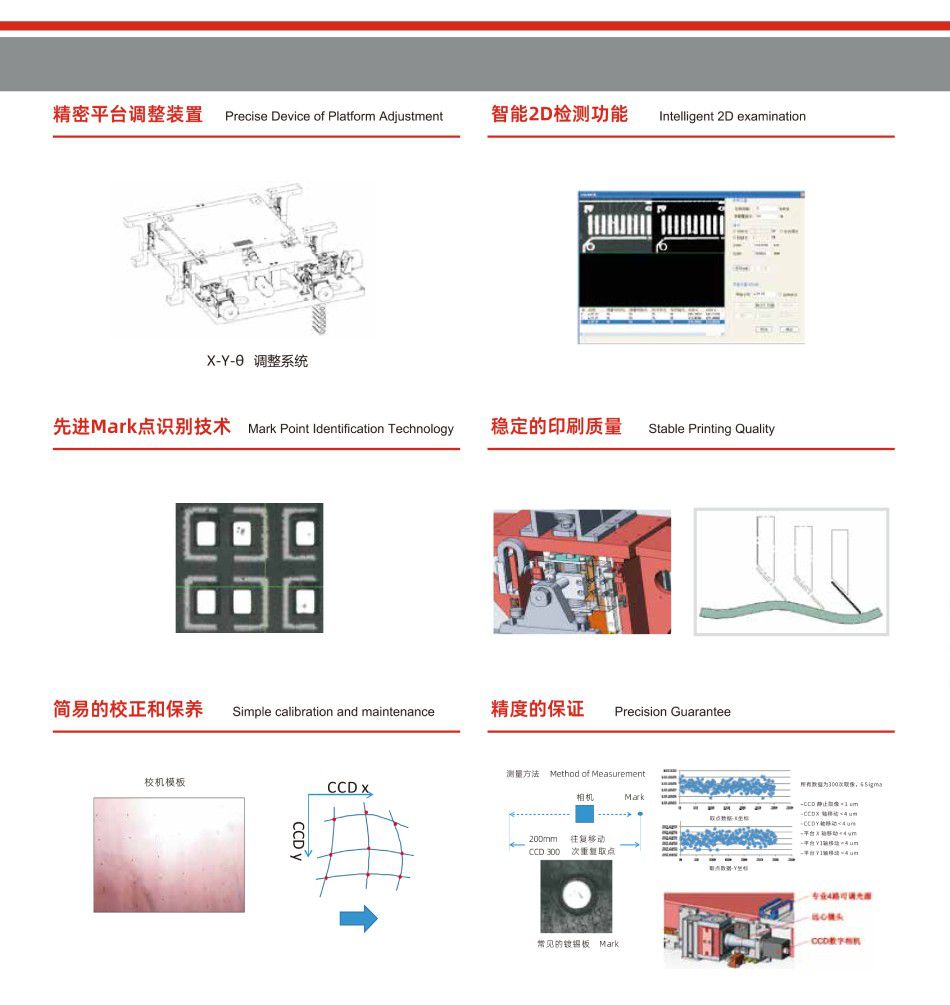

Alignment Position method: Mark automatic alignment

Camera: Germany BASLER,1/3” CCD,640*480pixel,pixel size:5.6μmx5.6μm

Acquire image method: Up/under double photo

Camera Light: Coaxial light,Ring light four kinds light can adjustable

View Range: 9mm*7mm

Mark dimensions: Diameter or Side length 1mm~2mm,allowable offset 10%

Mark Shape: Cir,Rec, or rhombus etc

Mark Position: PCB dedicated mark or PCB pad

2D detection: Standard

- Accuracy

Table Adjustment Range: X=±3mm,Y=±7mm, θ=±1.5°

Positional Accuracy: ±0.01mm

Printing Accuracy: ±0.025mm

- Time

Cycle Time: <10s (ex print, cleaning time)

Convert line Time: <5min

Programming Time: <10min

- Control System

Computer Configuration: Industrial PC,Windows official system

System Language: Chinese、English

Pre and next machine :Connection SMEMA

User authorization: User PW and Senior PW set

- Cleaning System

Cleaning System: Dry and Wet (standard),vacuum model (option)

Liquid Level Detection: Liquid level auto alarm detection

- Power Parameters

Main Power Supply: AC 220V±10% 50/60HZ Single phase

Total Power: Approx.3kw

Main Air Supply: 4.5~6kgf/cm2

Machine Weight: Approx. 900Kg

Machine Dimension: 1140(L)x1380(W)x1530(H)mm (standard) /1675(L)mm (add loading unit)/1675(L)mm(add buffering unit/ 2210(L)mm (add loading and buffering unit)

- Option

Pneumatic Top Clamp: For thin PCB (thickness ≤1mm)

Top clamp + side clamp: For PCB (thickness ≤1mm)

Vacuum Adsorption and unloadding: For PCB (thickness ≤1mm) and FPC

Auto tin added: Auto tin added

Auto Loading and Unloading: /

Flexible and Universal Suppor: For the double-sided PCB(PCB backside parts Height ≤ 9mm)

Automatic Positioning of screen frame

PCB Thickness Auto Adjustment Function

Squeegee Pressure Feedback Function

Air conditioner: Customer can buy by themselves

The rest of Solder Paste on the stencil Monitoring System

SPI close loop

UPS power off protection: UPS 15min power off protection

Industry 4.0: Bar code trace function,production analysis etc

Catalog