Get exclusive volume discounts, bulk pricing updates, and new product alerts delivered directly to your inbox.

By subscribing, you agree to our Terms of Service and Privacy Policy.

Direct access to our certified experts

Get exclusive volume discounts, bulk pricing updates, and new product alerts delivered directly to your inbox.

By subscribing, you agree to our Terms of Service and Privacy Policy.

Direct access to our certified experts

Heating system

- Heating zone structure: 12 heating zones, 24 heating modules

- Heating zone length: 4390mm

- Heating up time: 25min

- Outlet Exhaust Diameter,valume: 2-Φ145,Exhaust demand 10m³/min x2

Cooling system

- Cooling type: Three cooling zones:forced water cooling

- Cooling zone length: 1250mm

- Chiller power: 5P Water chiller

Conveyor system

- Conveyor Type: Chain + mesh belt synchronous transmission

- Conveyer Direction: L→R,R→L

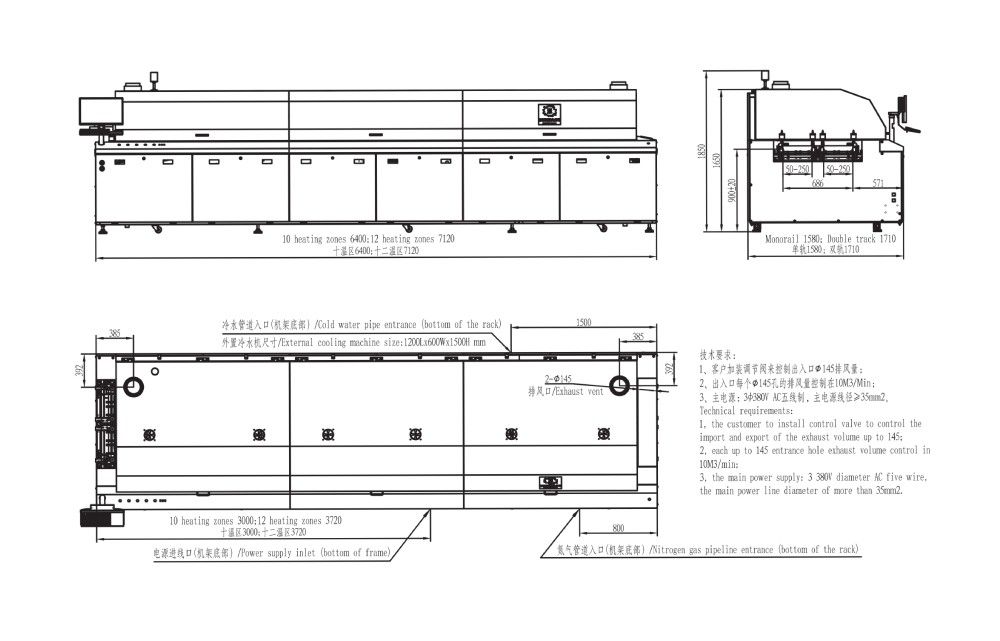

- Converyer Height: 900±20mm

- Component Height: Clearance above 30mm, Clearance below 25mm

- Conveyor Speed: 300mm-2000mm/min

- Guide rail structure: Dust free special hardened guide rail

- PCB Width: min 50mm-max 250mm (Dual tracks); min 50mm-max 450mm (Single track)

- Fixed Rail Mode: The front and rear guide rails are fixed, and the middle two guide rails are movable

Control system

- Power: AC3Ø 5W380V 50/60HZ

- Total Power: 117KW

- Startup Power: 42KW

- Normal consumption: 13KW

- Temp Control Range: Room temperature to 320℃

- Control type: PC+PLC Control system

- Temp Control accuracy: ±1℃

- PCB Temp Deviation: ±2℃

- Data Storage: Process Data and status stotage

- Power Outage Protection: Equipped with UPS

- Operation Interface: Windows Chinese simplified, English online free switching

- N2 area: Full nitrogen filling(The model with ""N"" refers to the nitrogen model)

- MES: Standard

- Computer: Commercial computer

General

- Dimension(LxWxH): 7120*1710*1650mm

- Weight: 3500-3700kg

- Flux recovery system: Standard

- Color: Bright wrinkled white

◆High heat energy, low energy consumption, high power motor matching wind wheel,theoretical and practical verification; under the same conditions set, can ensure the small and large components to achieve the minimum heat absorption difference,and achieve the best thermal balance;

◆The latest thermal insulation technology and the new furnace structure design can effectively reduce the furnace surface temperature and reduce the heat loss;

◆Imported PLC program controller, stable and reliable performance,high precision of temperature control and curve repetition;

◆Double-sided guiderail with special hardening treatment, strong and durable,repeatable use, cost saving up to 50%;

◆Online maintenance of rosin recycling system, modular design,convenient maintenance, reduce maintenance time;

◆Patented hotair system, hotair convection conduction more efficient, faster heat compensation;

◆Built-in real-time monitoring system of furnace temperature,which can automatically generate furnace temperature curve(option) ;

◆Intelligent data can be traced and uploaded toMES system.