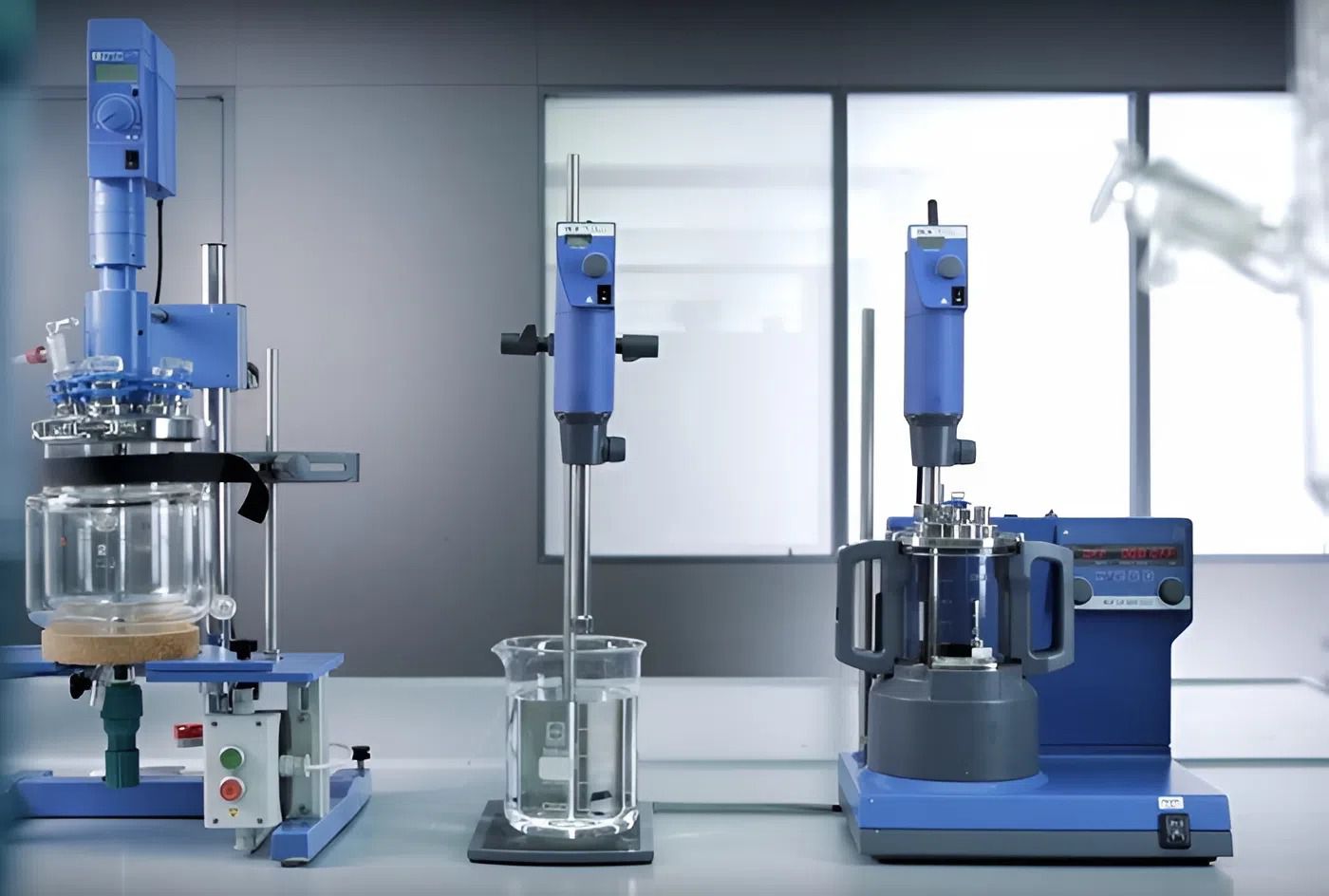

Homogenizer

A sample homogenizer is used to handle situations like these. Instead of manual stirring or prolonged mixing, the homogenization process helps the mixture become smoother and more uniform in a short amount of time.

When a sample homogenizer is needed

The need usually arises when working with oil and water emulsions, solutions containing poorly soluble powders, or suspensions that settle easily. Food, cosmetic, and pharmaceutical testing laboratories encounter these types of samples on a daily basis.

If measurement results vary between repeated tests, the cause is often uneven sample preparation. Homogenization helps reduce errors caused by uneven distribution, which is especially important for analyses that require high repeatability.

How a sample homogenizer creates a smoother mixture

The operating principle is based on strong shear forces generated by high rotational speed. When the liquid passes through the homogenizing head, larger particles are broken down into much smaller sizes. As a result, oil disperses more evenly in water, and poorly soluble powders are distributed more uniformly.

This process does not change the chemical nature of the solution. The main purpose is to improve structure and stability for subsequent analysis or research.

Types of solutions commonly processed

The most common are oil in water or water in oil emulsions. After homogenization, phase separation is significantly reduced, the surface becomes smoother, and the solution remains more stable when left standing.

Suspensions containing fine solid particles are treated in a similar way. The particles are evenly distributed throughout the liquid, limiting rapid settling at the bottom. This is especially useful when multiple samples are taken from the same container.

Other applications include lightly viscous mixtures, solutions with moderate viscosity, or small scale formulation test samples.

Practical benefits of using a sample homogenizer

Preparation time is significantly reduced compared to manual stirring. The desired level of uniformity can be achieved within just a few minutes.

Analytical results are more consistent between measurements. This helps save sample material, reduce effort, and minimize the need for repeated testing.

The workflow becomes more streamlined, especially when processing many samples in a single day. Operators can also more easily control solution quality before moving to the next step.

Who it is suitable for

Students conducting laboratory experiments use it to prepare samples more quickly and evenly. Quality control staff need it to ensure repeatability between measurements. Product development teams use it to test formulations before scaling up.

A sample homogenizer is not intended to handle overly complex problems. Its main role is to make solutions smoother, more stable, and easier to work with. When the preparation step is well controlled, the entire downstream analysis process becomes simpler.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-