No guarantee of operational quality

Mechanical wear changes working parameters

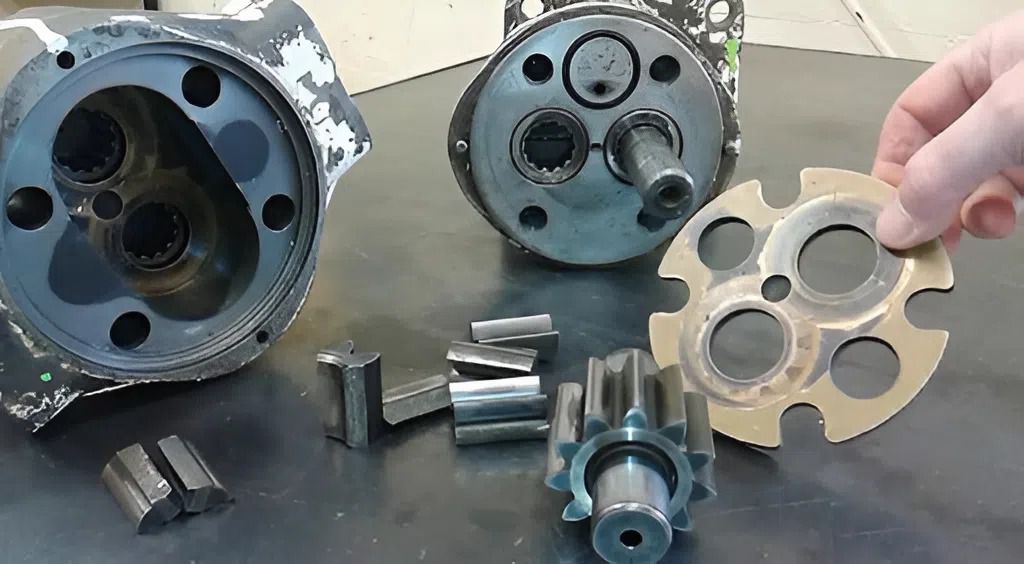

Old hydraulic pumps often have been operating at high pressure for many years. Internal components such as pistons, tilt discs, bearings, seals and vanes are constantly subject to friction, resulting in wear and deviation from design tolerances. When the pump can no longer achieve its rated pressure, the transmission system must compensate for the load, increasing friction, generating heat and consuming energy. Actual efficiency gradually decreases, while the stability of oil flow and output pressure is no longer as good as before.

Affects the entire hydraulic system

The pump is the main power source of the entire system. If the flow or pressure is unstable, the distribution valves, cylinders and hydraulic motors will also operate incorrectly. The system is prone to jerks, oil leaks or sudden pressure drops. Seemingly small errors in the pump can spread to the entire control cluster, reducing the life of the equipment and causing instability in factory operations.

Risks in maintenance and operation

Old pumps are difficult to maintain the tightness and concentricity of the shaft. After each maintenance, the working performance often cannot return to the original state because the assembly tolerance has changed. The need to periodically replace the seal, bearing or piston assembly causes the equipment to be constantly stopped for inspection, directly affecting the production progress.

Hydraulic systems operate at high pressures, sometimes exceeding 200 bar. If the pump leaks or cracks, the pressurized oil can spray out, causing burns or fires. High temperatures from compressed oil and friction between components can pose a fire or explosion risk if not controlled promptly. A system is only safe when the pressure-bearing components are in good technical condition, and this is almost impossible to achieve with equipment that has been used for many years.

To learn more about Hydraulic Pumps, see the following article:

Structure and operating principle of hydraulic pump

New hydraulic pump delivers superior performance and durability

Current hydraulic pump lines are designed with anti-wear alloy materials, optimal pressure regulator assembly and circulating cooling mechanism to maintain stable pressure for a long time.

For example, the EMEADS QQ-700 electric hydraulic pump distributed at emin.vn uses a high-power motor, precision transmission system and automatic overload protection mechanism. The pump operates smoothly, has stable flow, reduces oil loss and limits heat generation during operation.

Conclude:

In short, the hydraulic pump is the center of energy transmission of the entire system. A used device cannot maintain the same tightness, precision and load capacity as a new device. Choosing a new and genuine pump helps the system operate stably, maintain high performance and ensure safety for the operator. Refer to the types of hydraulic pumps at: EMIN hydraulic pump