In the market, the two most commonly used technologies are vane flow meters and ultrasonic flow meters. Each type has its own way of working, advantages and limitations, suitable for each specific business requirement.

How each type works

The propeller air flow meter operates on a mechanical mechanism. When the air flow passes through, the propeller inside the body will rotate at a speed proportional to the air flow rate. The sensor records this rotation speed and converts it into a displayed flow value. This is a fairly simple principle, easy to operate and is often applied to many traditional systems.

In contrast, ultrasonic gas flow meters use the principle of sound wave propagation to determine the gas flow rate. The device emits two beams of ultrasonic waves in the downstream and upstream directions. The time difference between the two directions of propagation allows the gas velocity to be calculated, thereby accurately determining the actual flow rate. Due to the lack of moving parts, this type of meter has less wear and tear and a significantly longer service life.

Applicability of both

Vane flow meters often have larger errors due to the effects of mechanical friction, dirt or pressure changes in the pipeline. However, systems that do not require too high accuracy such as compressed air measurement, civil gas monitoring or food applications, this type of device still brings good economic efficiency.

Ultrasonic gas flow meters have outstanding accuracy and operate stably even in environments with changing temperature, pressure or humidity. In particular, they can measure very small flows, which is difficult for mechanical devices to meet. Therefore, industries such as chemicals, oil and gas, semiconductors or medicine often prioritize the use of ultrasonic technology.

Investment cost for a device

One of the factors that businesses consider is the initial investment cost and long-term maintenance costs. The propeller type is cheaper and easier to install, but because of the rotating parts, it needs to be checked and cleaned periodically. In environments with many impurities, the life of the equipment can decrease faster.

In contrast, ultrasonic gas flow meters require almost no regular maintenance. Due to the lack of mechanical parts, the equipment operates stably and is less prone to failure. Although the initial investment cost is higher, considering the long service life and low operating costs, ultrasonic technology offers better overall performance.

Practical applications in various fields

Vane Air Flow Meter

The propeller air flow meter is one of the most popular devices today thanks to its simple structure, easy maintenance and low investment cost. This device operates based on the principle of rotation of the propeller when the air flow passes through, thereby determining the flow and speed of the air flow. Thanks to the advantages of price and durability, this type of machine is often chosen for applications that do not require too high accuracy or in clean air environments with few impurities.

In pneumatic systems, vane flow meters help monitor the amount of compressed air supplied to production equipment and tools, supporting energy consumption control and leak detection. In the food and beverage industry, the device is used to measure the flow of CO₂ or nitrogen in the filling and packaging process, ensuring a stable and safe process. In addition, in heating or boiler systems, it is also used to monitor the flow of combustion gas, helping to optimize performance and save fuel.

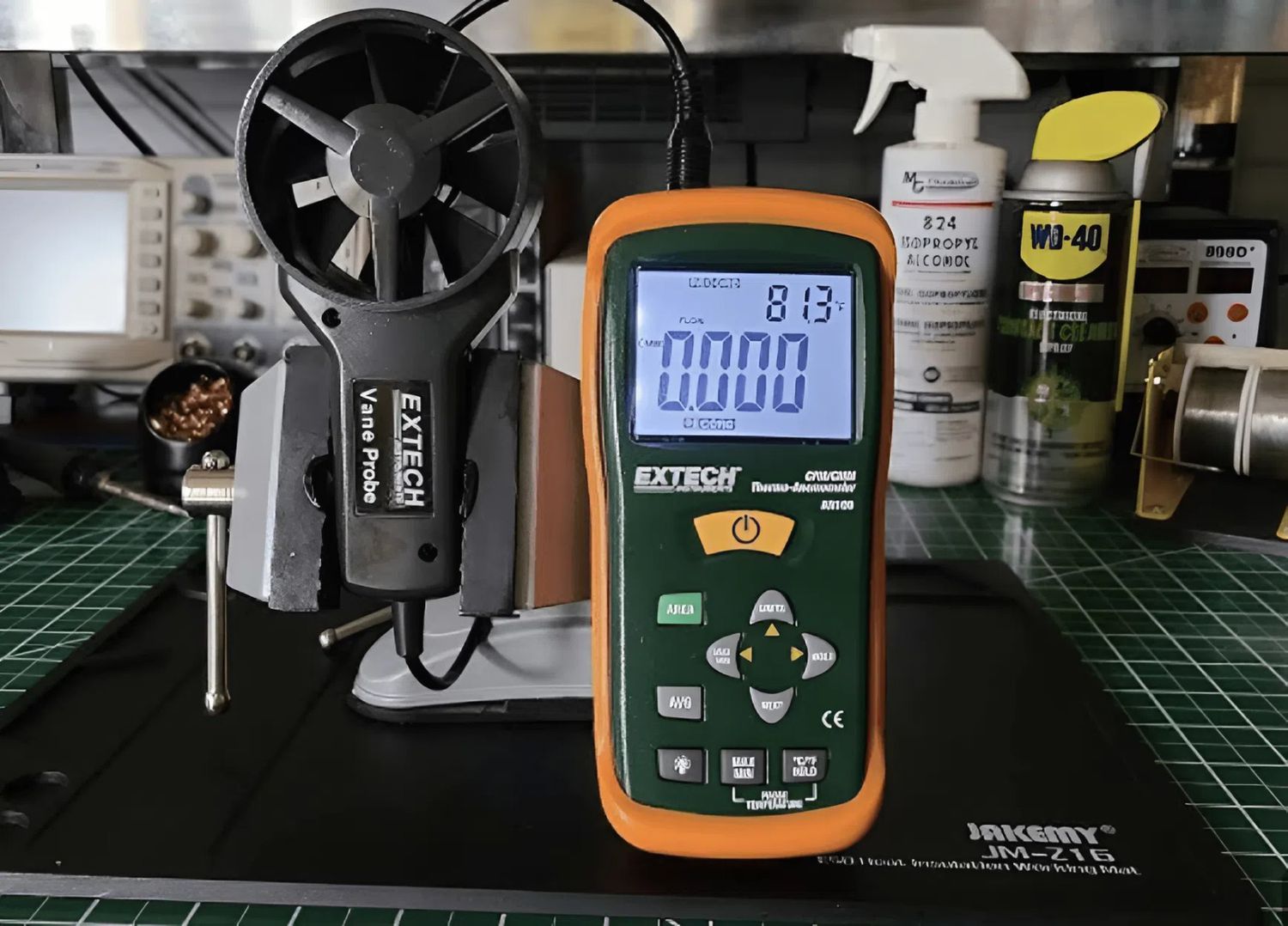

Reference: EXTECH AN100, anemometer, air flow and temperature meter.

Ultrasonic gas flow meter

This is a line of devices designed for applications that require high precision and stable operation in harsh environments. Instead of using mechanical parts such as fans, this device operates based on the principle of transmitting ultrasonic waves through the gas flow, calculating the transmission time between probes to determine the actual flow. Thanks to non-contact measurement technology, the device can operate durably, less affected by pressure, temperature or impurities in the gas.

In the chemical and petroleum industries, ultrasonic gas flow meters are used to monitor corrosive or toxic gases, ensuring operator safety. In the medical and pharmaceutical industries, the device plays an important role in controlling the flow of oxygen and medical gases, serving the gas distribution system in hospitals or laboratories. In the semiconductor industry, where absolute purity is required, ultrasonic meters help ensure ultra-clean gas flows without impurities. In addition, this device is also used in commercial systems to measure gas flow with high accuracy, serving the purpose of control and payment.

With stringent requirements for accuracy and reliability, TES-3142 is the right choice.