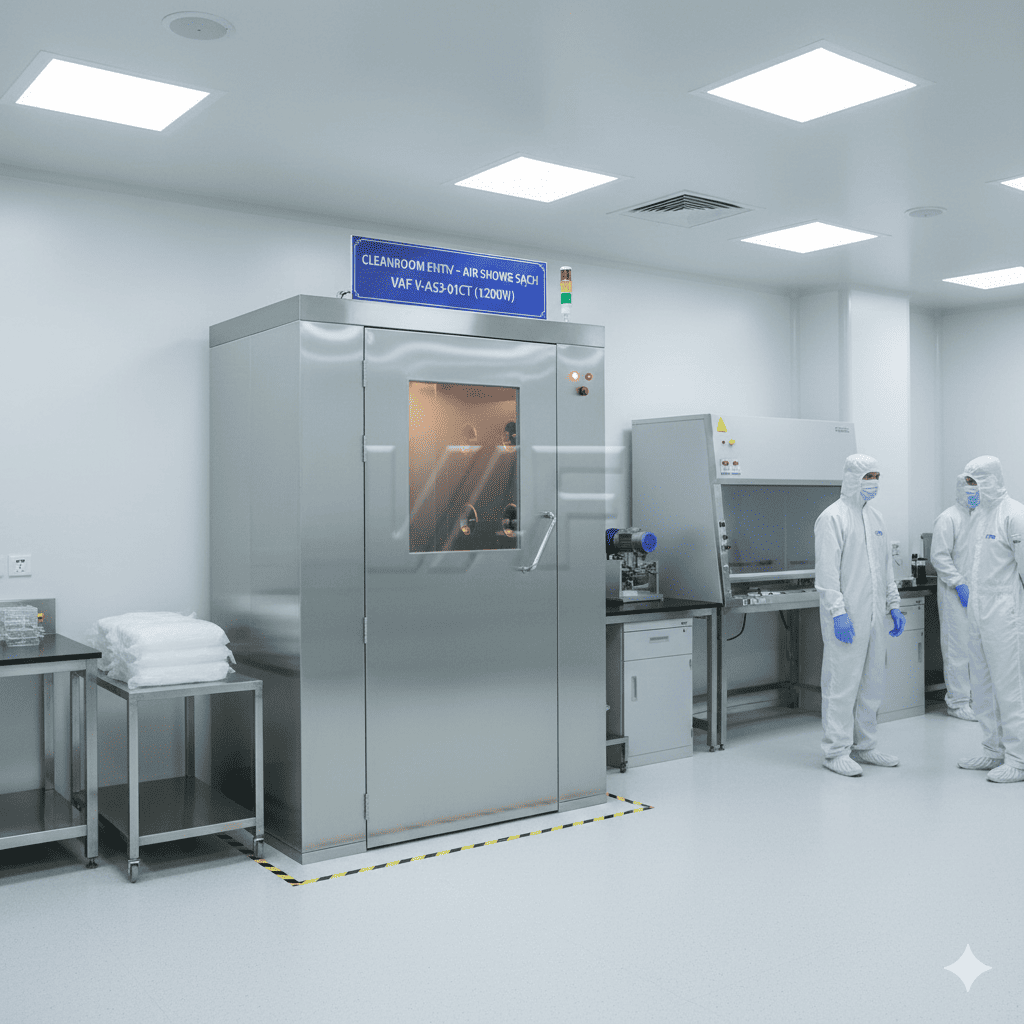

The role of air chamber in GMP clean room system

The air chamber is an intermediate device located at the entrance of the clean room, with the task of removing dust, microorganisms and impurities on clothes, shoes, trolleys or materials before entering the production area. Thanks to the high-speed clean air flow combined with HEPA filter, the air in the chamber is continuously cleaned and blown directly onto the surface to be cleaned at a speed of about 20-25 m/s.

More than just an auxiliary device, the air blower plays a key role in maintaining a stable cleanliness level, ensuring product quality and optimizing long-term operating performance.

Installing a standard air chamber will help businesses:

Legal compliance with meeting the mandatory requirements of regulatory agencies (e.g., Drug Administration, Ministry of Health) on GMP, ISO, HACCP standards.

Maximum pollution control, long-term stability of cleanliness level, reducing the load on the main air filtration system (AHU, HEPA box) inside the clean room.

Protect product quality and optimize production, prevent product damage due to contamination, thereby minimizing the rate of defective products, saving on recycling or disposal costs.

Therefore, installing a GMP-standard air chamber is a smart investment for the sustainable development of the business.

GMP standard air chamber installation process from A to Z

1. Site survey and installation location determination

The installation process of the air chamber requires high technical skills to ensure air tightness and optimal performance. And the first step in the air chamber installation process is to survey the actual construction area. The installation engineer will evaluate the direction of personnel movement, the clean room connection location, the installation space and the ability to supply electricity and gas.

The location of the air chamber must ensure one-way flow, avoiding reverse intersection causing reverse contamination. This is a key factor determining the efficiency of future operations.

2. Technical design suitable for cleanroom level

Depending on the cleanroom level (ISO 7, ISO 8, GMP C, GMP D…), the configuration of the air chamber will be considered and the design factors will be decided including:

+Number of air nozzles

+Air speed

+Fan capacity

+Type of HEPA filter

3. Construction of frame, shell and electrical control system

The air chamber is usually made of 304 stainless steel or powder coated steel, ensuring durability and corrosion resistance. When installing the air chamber, the interlocking door system, infrared sensor, control panel and power source must be connected absolutely precisely.

The interlocking system helps ensure that the two doors do not open at the same time, avoiding pressure loss and limiting dust from outside into the clean room.

4. Install the fan, filter and air duct system

The high-power centrifugal fan is responsible for creating a strong airflow, while the HEPA filter retains up to 99.97% of dust particles ≥ 0.3 microns. The entire system must be sealed to ensure no air leaks. Only when this step is up to standard will the air chamber truly perform its full potential.

5. Test run, calibration and acceptance

After completing the construction, the air chamber will be tested, measuring wind speed, air cleanliness, noise level and checking the operation of the interlocking door system. This is a mandatory step before putting the equipment into official use in the production line.

Tham khảo thêm tài liệu để hiểu rõ hơn về thí nghiệm thổi khí phòng thí nghiệm:

Kiến thức cần biết về thổi khí sạch vào phòng

Những lưu ý khi sử dụng Airshower- thổi khí mà bạn nên biết

So when does a business need to upgrade or install a new air chamber?

In fact, many air chamber installation systems do not achieve optimal efficiency because they ignore important technical factors. Learning from these common mistakes will help businesses ensure the quality of their clean room systems.

Enterprises should consider installing a new air chamber or upgrading when there is a change in production scale such as expanding the factory or production line. In addition, upgrading the clean room level according to new GMP standards also requires equipment to meet the corresponding standards. If the frequency of entry and exit increases, the risk of cross-contamination is high, or the old system operates poorly, and the dust filter is ineffective, it is time to take immediate action. Investing in installing an air chamber at the right time will help enterprises save a lot of costs in troubleshooting later and ensure continuous and effective production operations.

Optimal air chamber installation solution from EMIN

With many years of experience in implementing cleanroom projects, EMIN offers a complete air chamber installation solution from design consultation, construction, and acceptance, you can refer to: EMIN Air Shower

Not only providing equipment, EMIN also supports consulting on the correct GMP-level configuration, providing full equipment to measure wind speed, pressure, and dust for acceptance testing, maintenance, and periodic replacement of HEPA filters.