In reality, many small factories or QA departments are using mechanical rulers or touch dial gauges for measurement, but when the part is only a few mm in size, soft or easily scratched, the measurement results are not only inaccurate but also time-consuming, even compromising on quality.

Problem Solving in Manufacturing

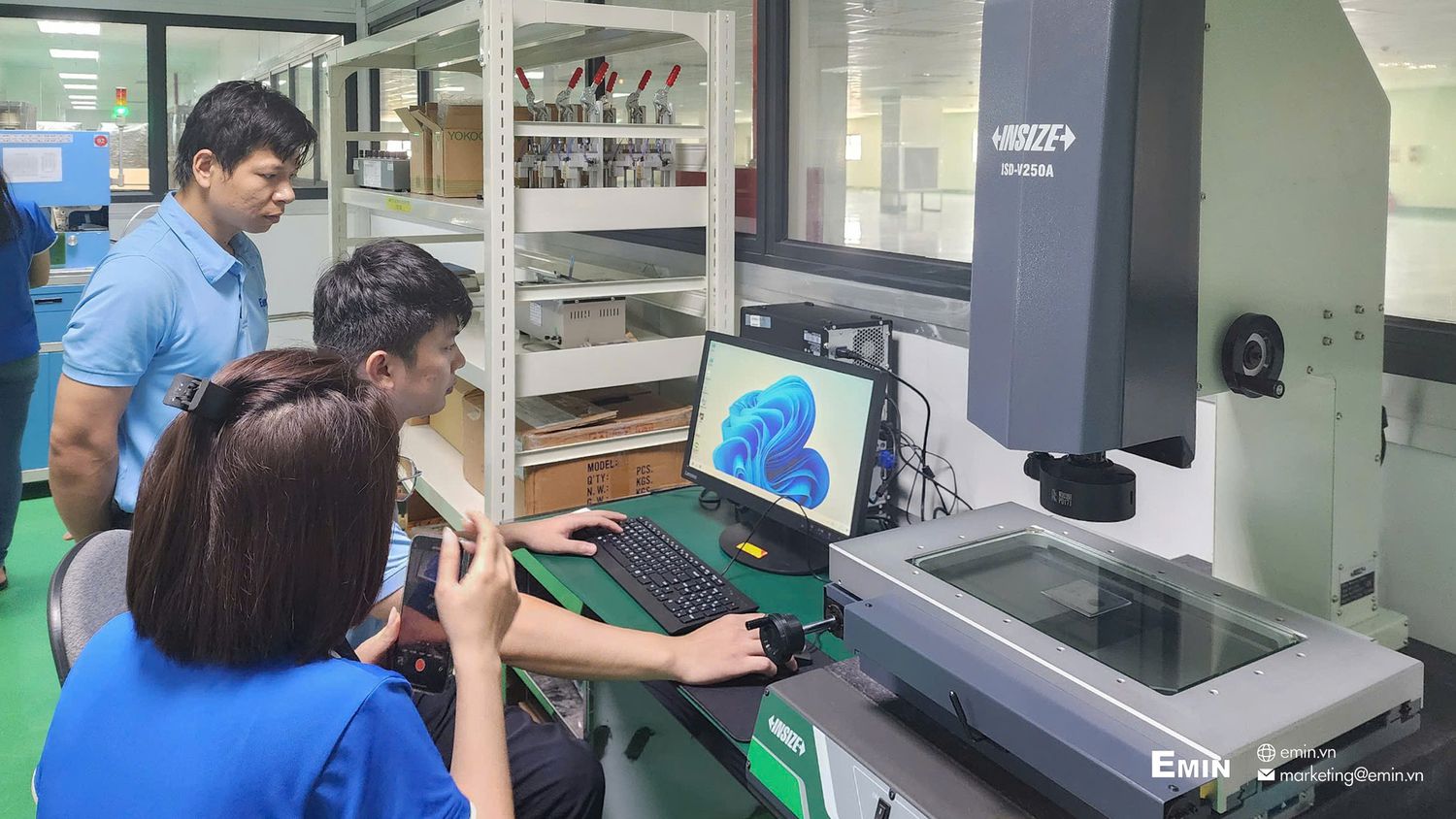

When customers first come into contact with the INSIZE ISD-V250A 2D optical measuring machine, they often wonder whether this device can really help measure quickly, measure accurately, can update data into the existing QC system, and whether the investment cost is worth the actual value it brings. These are understandable concerns, because many businesses have invested in very expensive automatic CNC measuring machines, which are complicated to operate, but are not necessarily suitable for small details or need flexible changes.

Customer Experience After Experience

In fact, the INSIZE ISD-V250A 2D optical measuring machine brings a completely different experience. When measuring a 1 mm thick thin plastic part, the operator only needs to place the part on the glass table, adjust the optical zoom and use the automatic contour analysis software. The magnification from 29X to 184X helps to enlarge small details on the built-in computer screen. The X/Y/Z measuring range is 10" × 6" × 8" (~250 × 150 × 150 mm), suitable for a variety of details in molds, small mechanical products or electronic components.

Fast Measurement Performance

Another factor that makes many customers switch from manual contact measuring machines to optical measuring machines is the speed and efficiency in repetitive measuring shifts. For parts that need to be measured in small batches or parts with complex shapes, fast operation without complicated calibration before each measurement is a big advantage. The INSIZE ISD-V250A 2D optical measuring machine ensures accuracy within ≤ (2.5 + L/100) μm, with repeatability ≤ 2 μm on a manual mobile table, meeting advanced quality requirements in the light industry and plastic parts manufacturing industry.

Outstanding Features Of INSIZE ISD-V250A

However, there are still some points to note for effective use. As a manual measuring machine, the operator needs to master the process of placing the part, aligning the X, Y and Z axes, as well as adjusting the surface LED light and contour to avoid ghosting or unclear edges. If the calibration is not according to the manufacturer's standard glass plate or the ambient temperature is not stable, the measurement results may be skewed. During use, uneven lighting can cause the software to misidentify the contour, leading to inaccurate reporting. In addition, the glass table with a maximum load of about 20 kg must be observed.

Real Life Success Stories

A memorable story in the EMIN customer community is the case of a QC measuring room at an electronic components factory. When checking a batch of 500 plastic housing parts with a small tolerance of ±0.05 mm, they used to spend hours measuring each part with a touch dial gauge. When switching to using the 2D optical measuring machine INSIZE ISD-V250A, the same operation only took nearly half the time and the results could be compared for each part, and reports could be saved quickly. They not only saved time but also increased measurement consistency, easily detected over-tolerance errors and handled them quickly.

Advantages Compared With Other Measuring Devices

Unlike complex CNC machines, the INSIZE ISD-V250A 2D optical measuring machine has a built-in computer and measuring software. The 1/3" color CCD camera sensor with 0.3 MP resolution provides clear images. The zoom is manually adjusted but smoothly from 0.7X to 4.5X, corresponding to a magnification of 29X to 184X on a 19-inch screen, enough to see small details such as hole diameters or thin shell profiles.

One point that many engineers appreciate is the ability to record and track measurement data. The software can save measurement results for each detail, create traceability reports, helping QA units easily retrieve results from different production batches. This is a big advantage compared to traditional manual measuring methods, which require a lot of recording and are prone to errors.

Technical Support and Service

In the production environment, the parts have curves, thin shells, small holes, if using a contact machine, it can scratch the surface or cause slight deformation. Meanwhile, the 2D optical measuring machine INSIZE ISD-V250A measures completely by image, non-contact, preserving the original. This is something that many customers in the plastics, molds and plastic components industry highly appreciate: the parts are almost not reprocessed after measurement, saving the additional step of re-inspection.

Before investing, some customers are concerned about the cost of maintenance and periodic calibration. However, INSIZE provides calibration glass plates along with periodic calibration services performed at EMIN's facilities. We provide technical support from domestic to international, helping customers feel secure throughout the process of using the equipment, especially when ISO certification or verification according to international standards is required.

See products in Category: CNC, 2D, 3D measuring machines

Conclude

When considering between traditional tactile measuring devices, 3D CNC measuring devices, or optical machines, the real value of the INSIZE ISD-V250A 2D optical measuring device lies in the balance between investment cost, measurement efficiency, flexibility, and ease of operation. Although not fully automated, the device still allows users to operate quickly, have digital data, easily integrate quality management systems, and especially does not require highly specialized operators.

If you are looking for a non-contact geometry measuring device that combines reporting software, high magnification, and an ideal measuring range for medium to small parts, the INSIZE ISD-V250A 2D optical measuring device is a wise choice. Suitable subjects include QA/QC departments, precision mechanical workshops, plastic manufacturing, CNC machining, and electronic components. With technical support from EMIN and the device's practical feature set, you can be confident in the value of your investment.