Overcoming challenges when constructing in confined spaces

On construction sites, many installation locations are deep inside machine recesses, close to the ceiling, or within technical cabinets. Limited workspace makes it difficult to use large tools, or even impossible to reach the required pressing point.

Modern form-fitting pliers are designed with compact pressing heads and optimized handle opening angles. This allows the tool to fit into narrow spaces while still providing sufficient pressing force. The pliers' heads can rotate flexibly, allowing for adjustment of the pressing direction without changing the user's standing position, reducing operation time and minimizing collisions with surrounding equipment.

Ensuring a tight seal through concentric pressure

Une uneven pressure distribution around the pipe circumference is a common cause of leaks after installation. With manual methods, the pipe ends are prone to localized deformation, creating very small gaps that are difficult to detect with the naked eye.

Hydraulic crimping mechanisms distribute pressure evenly from multiple directions to the center of the pipe end. This process maintains the pipe's shape, limiting dents or cracks. When the pressure is evenly distributed, the joint achieves a tight seal across the entire contact surface, suitable for fluid or gas systems operating under high pressure.

Optimize time for mobile maintenance work

In industrial maintenance, downtime directly impacts operating costs. Disassembling an entire pipeline just to address a single faulty connector is often not a cost-effective solution.

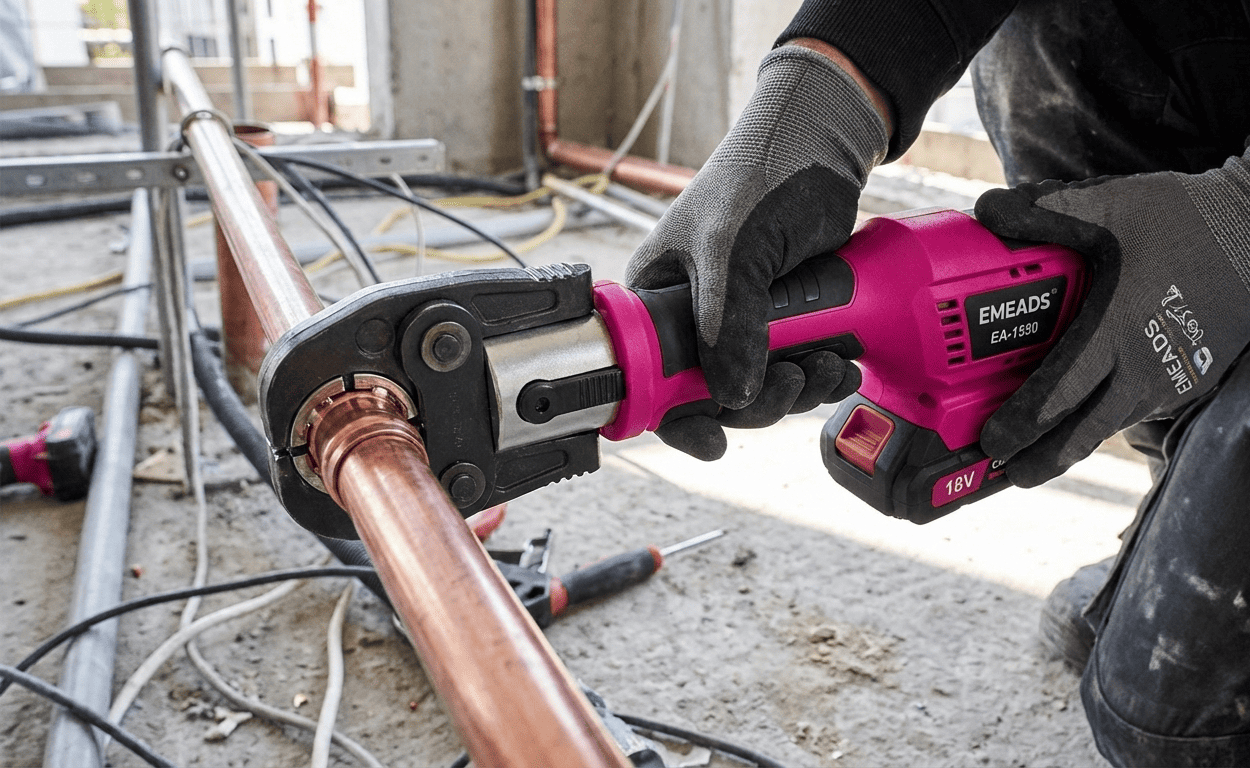

Handheld crimping tools allow technicians to work directly on-site without complex preparation. Devices like the EA 15100 enable quick and easy crimping with just the push of a button. Standard crimping jaws ensure high repeatability, completing the connection on the first attempt and minimizing the need for rework.

View the full product range at: Pipe end forming crimping pliers

The automatic mechanism helps control the clamping force and increase safety.

Over-pressing is a common error during construction, which can weaken the pipe end or damage the clamp jaws. This error is difficult to control relying solely on the operator's feel.

The integrated pressure sensor system automatically shuts off and returns the clamp jaws to their original position when the designed force is reached. This ensures consistent joint quality, regardless of the user's experience. The non-slip handle design and balanced weight distribution allow workers to work continuously for extended periods while maintaining stability and accuracy.