The role of the press in sample analysis standards

The sample press is an important intermediate step that helps fix the material sample in a hard plastic mold, creating a sample with standard size, flat surface and easy to manipulate in the next steps. Thanks to the sample pressing process, small, thin or complex-shaped samples are firmly reinforced, avoiding deformation when grinding, polishing and ensuring that the area to be observed is always in the correct position.

During the entire process of preparing metal samples, mounting machines helps standardize the size, increase stability when clamping, keep the analysis surface clean, and reduce errors due to manual operations.

To eliminate this error, we usually have only two main methods: Hot Press and Cold Press. Each method has its own mechanism to handle air bubbles, and understanding this is the key to mastering sample quality.

Hot Pressing, Pressure Mechanism and Fluidization of Plastic

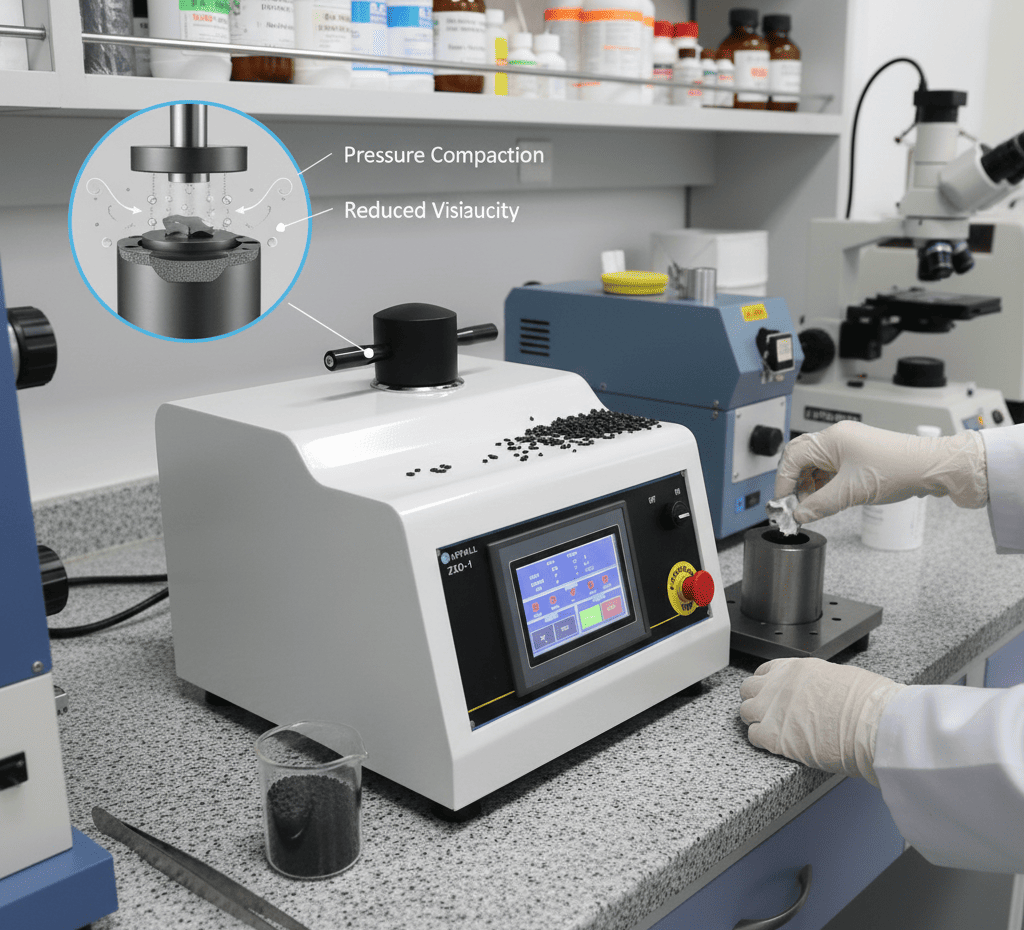

The Hot Mounting method uses a specialized device that combines two powerful physical factors: high temperature and high pressure. This is a forced process, aiming to create a molded sample with almost absolute tightness.

Forced Compression: When the molding machine operates, high pressure (usually 200 bar or more) will compress the entire molten plastic block. This pressure will force the trapped air bubbles inside to shrink or melt out of the plastic block, no longer able to exist as a significant sized void.

Viscosity Reduction: High temperatures cause the molding resin (usually a thermosetting resin) to become extremely fluid. This fluidity allows the resin to flexibly flow into and fill any microscopic cavities, gaps, or cracks in the surface of the specimen that the resin cannot do under normal conditions.

It is the combination of the high fluidity of the material and the powerful pressure applied by the machine that makes hot pressing the first choice for samples that require absolute tightness and high uniformity. However, it is important to note that if your sample is sensitive to heat (e.g. some alloys have fusible phases), hot pressing can change the surface microstructure.

Refer to some products in Category: EMIN distributed sample presses

The secret to Cold Pressing is vacuum sealing

Cold pressing is a must for materials that cannot withstand high temperatures and pressures, such as electronic materials, polymers, or some special alloys. In this method, the resin is cured (usually Epoxy or Acrylic) by a chemical reaction.

Origin of Air Bubbles: The main problem with cold pressing is not the curing process itself, but the mixing of the resin with the curing agent. Manual mixing always creates a large amount of air bubbles that are trapped within the mixture.

Vacuum Solution: Instead of applying pressure, we use the opposite mechanism: reducing the pressure. Immediately after the resin mixture is poured into the mold, we place the whole thing in a vacuum chamber. The sudden reduction in pressure will cause all the air bubbles that are trapped inside the mixture to swell and be sucked out before the resin begins to cure.

If the vacuum step is omitted, cold pressing will almost certainly result in voids, especially in the crevices and corners of the specimen. Using a dedicated vacuum machine has transformed cold pressing from an error-prone manual method into an effective quality control process, ensuring that the material structure is preserved while achieving the desired density.