A weak power supply will not only cause the device to operate erratically but also pose a risk of fire due to overheating. This article provides the correct power calculation procedure to ensure the absolute safety of your system.

Correct understanding of three basic parameters on power supply

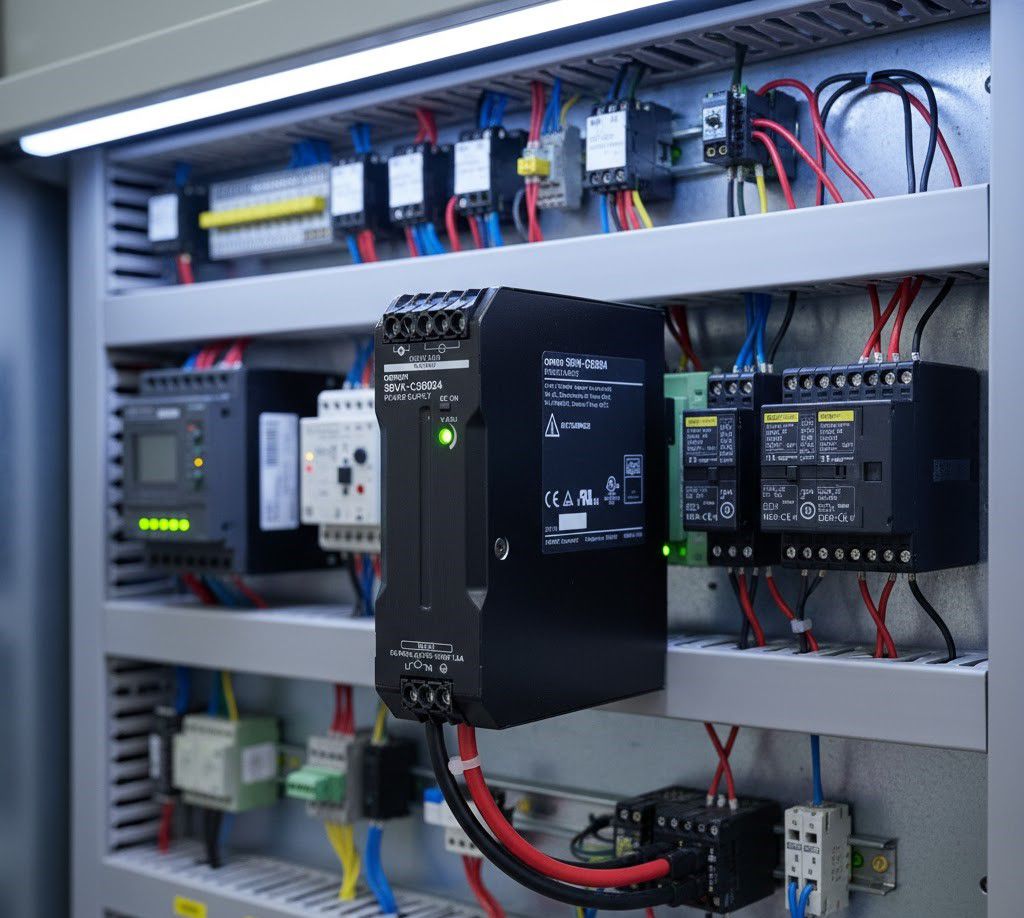

Before going into the calculation formula, you need to understand the three technical parameters that always appear on the labels of Omron, Autonics power supplies or any other type of honeycomb power supply.

1. Voltage or Voltage U:

This parameter is the output voltage of the power source and has the unit of Volt. You must choose a power source with a voltage that completely matches the device that needs power. If the device uses 24V and you supply 12V power, the device will not run. On the contrary, if you supply 48V power to a 24V device, the internal components will be destroyed immediately due to overvoltage.

2. Current intensity or Current I:

This quantity represents the maximum current supply capacity of the power supply and is measured in Ampere. Unlike voltage, the current of the power supply only needs to be greater than or equal to the current consumed by the device to meet the requirements. For example, if the device needs 2A, you can use a 5A power supply and it will still operate normally and be more durable because the power supply does not have to operate at full capacity.

3. Capacity or Power P:

This is a measure of energy consumption in Watts. Power represents the actual power of the power supply and is the product of voltage multiplied by current.

Formula for calculating actual power consumption

To choose the right power supply, you need to determine the total power that the load system will consume. The most basic physical formula applied to this calculation is:

P = U × I

The symbols are understood as follows:

P is power in Watts

U is voltage in Volts

I is current in Ampere

Analyze a real example:

Let’s say you need to install a LED strip light system for your kitchen cabinets. The LED roll packaging says 12V and the power consumption is 12W per meter of wire. You measure and plan to install 5 meters of wire running along the cabinet.

The total power consumption of 5 meters of wire will be:

12W × 5m = 60W

To find the required current, you apply the reverse formula:

I = P / U

I = 60W / 12V = 5A

The calculation results show that you need a 12V power supply with a minimum load current of 5A. However, if you buy a power supply with exactly 5A, there is a high possibility that the power supply will fail after a few months of use. The reason lies in the next part about safety factors.

80 percent safety factor rule when selecting a source

Industrial and civil electrical engineering has an immutable principle: never let the device operate at 100% capacity continuously. Electronic components inside the power supply such as capacitors, pulse transformers and power transistors will heat up very quickly when running at maximum load. High temperatures reduce the life of components and increase the risk of short-circuiting the insulation layer.

We need to apply the safety factor rule, also known as the backup factor. The most common safety level ranges from 20 to 30%. That is, the power supply should only operate at 70-80% of the design capacity to ensure coolness and durability.

Formula for calculating the power supply current to buy:

I source = I load × 1.3

Reapply the LED light example above with a calculated current consumption of 5A:

The ideal power supply current will be:

5A × 1.3 = 6.5A

In reality, the market often does not produce odd levels like 6.5A, so you will choose the closest higher standard power level. In this case, the 12V 10A power supply is the most optimal choice in terms of technology and economy. The 10A power supply when running a 5A load will be very cool and operate stably for a long time without worrying about overloading.

Special note for motorized loads

The above calculation method works very well for purely resistive loads such as LED lights, heating wires or surveillance cameras. However, if you use the power source to run DC motors, mini pumps, cooling fans or solenoid valves, the calculation will be much more complicated.

Devices with coils, also known as inductive loads, always have a large starting current. When the machine is first turned on, the current that activates the motor can spike 3 to 5 times higher than the normal operating current. Although this starting current only lasts for a split second, it is enough to puncture the protective components of a weak power supply or activate the Overload Protection mode.

Example with pump:

A 24V mini water pump has a working current listed on the label as 2A.

The actual starting current can be up to:

2A × 3 = 6A

If you buy a 24V 3A power source, the pump may never start because the power will automatically cut off as soon as you turn on the switch, thinking it is short-circuited.

The solution for this case is to choose a power source that can withstand instantaneous overload current well or choose a power source with a large capacity. A 24V 10A power source will be a safe choice to ensure the pump starts smoothly. Omron's high-quality power lines such as the S8VK or S8FS series often have better load charts and starting current capacity than floating power types.

See more at: DC adjustable power source ≤ 1KW

Distinguish between real power and virtual power

The current situation in the electrical equipment market is the confusion of technical specifications. Cheap and unbranded power supplies often have very high specifications but in reality, their performance is very low.

Many cheap honeycomb power supplies labeled 12V 30A equivalent to 360W can sometimes only operate stably at 15A to 20A. If you believe in the 30A specification and install it for a 25A consumption system, the power supply will explode or drop voltage after only a few minutes of operation. The phenomenon of voltage drop is that when the load is heavy, the output voltage can no longer maintain the 12V level but drops to 9V or 10V, causing the device to flicker, the light to dim or the camera to lose image.

The only way to avoid this risk is to choose to buy products from reputable brands with genuine distributors and full technical documents Datasheet. The product codes you see on EMIN such as Omron S8VS, S8VK or Autonics SPB all list the actual capacity. The manufacturer writes 5A which means the source can run continuously at 5A under standard temperature conditions.

How does ambient temperature affect power?

The installation environment factor is often overlooked but directly affects the performance. The performance of the power supply is inversely proportional to the ambient temperature.

If you install the power supply in a closed and narrow electrical cabinet without a ventilation fan or place it outdoors in the sun, the internal temperature can reach 50-60 degrees Celsius. At this temperature, the load capacity of the power supply will be significantly reduced. A 10A power supply at 60 degrees Celsius can only handle a maximum load of 6A or 7A.

Technical documents of major manufacturers always provide a temperature derating curve. System designers need to refer to this chart very carefully. If the installation environment is too hot, you are forced to choose a power supply with a much larger capacity than the original calculation or install a forced cooling fan system for the electrical cabinet.

Investing in a quality and properly sized power supply may cost more initially but will save you a lot of money in repairs later on. You will eliminate the risk of fire and ensure that your expensive machinery runs smoothly.

Would you like me to go into more detail about Omron's S8VK power supply compared to conventional honeycomb power supplies to see the difference in internal components?