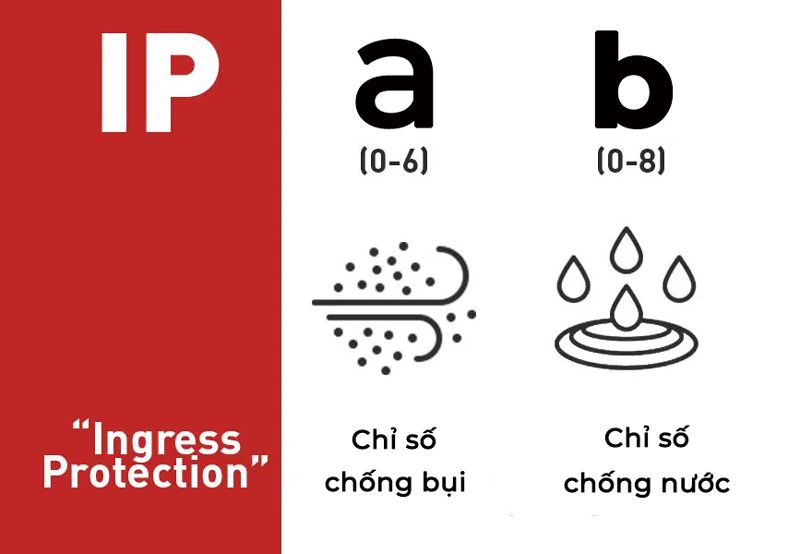

IP rating?

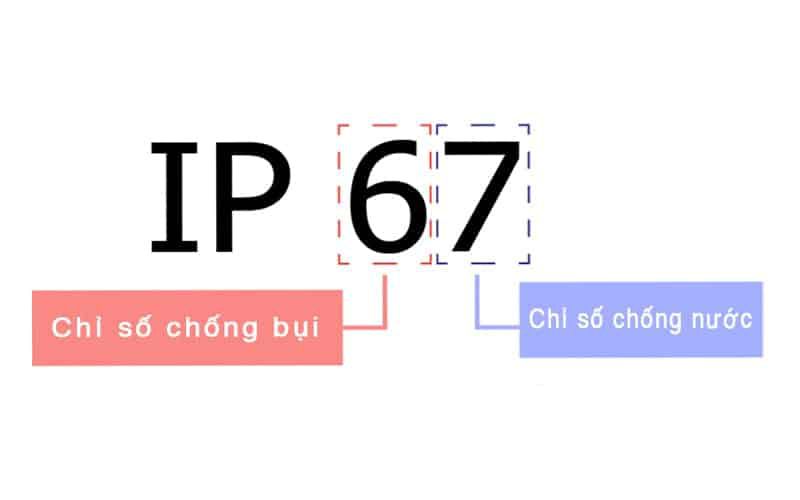

IP stands for Ingress Protection. It is an international standard that indicates the level of protection a device has against external agents such as dust, water or oil. The structure of the IP code consists of two digits. The first number represents the protection against dust and small solid objects, the second number represents the level of water resistance.

In fact, when working in a workshop or technical room, you will find that the air is rarely absolutely clean. It can be fine dust from the workpiece, moisture in the air or coolant splashed in. If the equipment is not designed to withstand these factors, the risk of errors or damage to the circuit board is entirely possible. Therefore, the IP index is like an indicator for you to recognize whether the equipment is suitable for your working conditions or not.

However, it is important to understand that having an IP rating on a caliper does not mean that the device is completely waterproof. For example, an IP65 micrometer can withstand light water pressure but cannot be directly immersed in water or left in the rain for many hours. The IP standard only reflects the ability to resist intrusion within certain limits, and should not be understood as absolute.

Currently, electronic measuring devices from major manufacturers are gradually equipped with appropriate IP standards, helping users feel more secure when using them in environments with humidity, dust or light oil without worrying about the device quickly degrading.

Why is the IP rating on calipers important on micrometers and digital calipers?

Many users think that when a measuring device is labeled IP67 or IP65, it means that it can be used comfortably in conditions with water, dust or oil without worry. But the reality is not entirely like that. Even if a micrometer model like Mitutoyo meets the IP67 standard, that does not mean that it will be completely immune to water if left submerged for a long time or used in a continuous humid environment.

Most of the current micrometers or electronic calipers are designed to achieve a relatively high IP index, most commonly IP65 or IP67. Achieving these standards helps the device to work more stably in dusty, humid environments or when exposed to light water jets. However, that level of protection is only within certain design limits, not absolute armor.

Another point worth noting is that the higher the IP index on the caliper, the higher the production cost and selling price of the device. That is understandable, because to achieve a better level of protection, the manufacturer must invest in waterproof design, sealed structure and suitable materials.

When choosing a mechanical measuring device such as a digital caliper or micrometer, do not ignore the IP index. This is a factor that directly affects the durability, stability and lifespan of the device during actual use. The electronic components inside only need to be exposed to a small amount of moisture to cause incorrect measurement results or cause the device to break down faster.

Detailed explanation of each common IP level (IP54, IP65, IP67...)

When looking at the IP index on the caliper, many people often only care about the higher the number, the better. However, understanding each level will help you accurately assess whether the device is suitable for your actual working environment, thereby avoiding buying too many features or choosing the wrong one.

With IP54, the device is protected at a basic level against dust and water. Specifically, dust can still get in at a very small level, but does not affect the operation of the device. As for water, it can withstand light water jets from all directions, such as when operating near areas with steam or coolant. IP54 is suitable for indoor environments, not too humid or with a lot of industrial dust.

Up to IP65, the level of protection is significantly improved. The device is almost completely sealed against dust, including fine dust particles. At the same time, it can withstand low pressure water jets from all directions, such as when working near CNC machines with coolant jets. This is the most common IP level on micrometers and electronic calipers today because it balances performance and cost well.

With IP67, the device reaches the threshold that can temporarily resist being immersed in water at a maximum depth of one meter for a short time. This is a high level of protection, often found on high-end measuring devices used in particularly humid environments or with a high risk of contact with liquids. However, users should not be subjective because the IP standard only protects under test conditions, not applicable to improper use such as prolonged immersion or allowing water to seep through openings due to aging of the device.

Quick comparison between IP and non-IP devices

The difference between a caliper with a clear IP rating and one without or without an IP rating is not just in the paperwork or specification sheet, but will be revealed clearly in actual use, especially in industrial environments.

For example, a Mitutoyo 500-752-20 digital caliper is equipped with IP67 standard, allowing users to operate in conditions with a lot of dust or moisture without worrying about water entering and damaging the internal circuit board. The device can resist light water jets, even withstand being submerged in shallow water for a short time, according to testing standards. This is especially useful when working in mechanical workshops or production areas with coolant, cooling water or steam cleaning.

On the contrary, if using an electronic caliper model with unknown IP standards, or basic models such as the standard 500-196-30 without obvious water resistance, users need to be more careful when operating near humid areas. If moisture gets into the microcircuit or condenses in the display screen, the device can report incorrect readings or be damaged beyond repair.

However, that doesn’t mean everyone needs to invest in the highest IP rating. In clean, stable environments such as labs or QC areas in factories with well-controlled conditions, a standard or IP54 model can still meet measurement requirements perfectly. The choice of equipment should be based on the specific usage environment, rather than chasing the highest index and incurring unnecessary costs.

You may be interested in:

The application of the size pair is also unknown

What is an electronic ruler? What is its configuration and its application

Conclude:

If you need more information or want more advice on suitable products, EMIN is always ready to support you in the most detailed and fastest way.