In reality, many jobs have been found where the electrical resistance to ground is measured at the next address but the final inspection or measurement step is omitted. Only when a problem occurs is it discovered that the resistance to ground is significantly higher than the permissible level.

How is earth resistance understood?

Simply put, ground resistance reflects how quickly or slowly current flows into the ground. The more conductive the soil, the faster the current flows, and the lower the risk of dangerous voltage buildup.

This value varies depending on the soil type, moisture content, compaction, groundwater level, and even the placement of grounding rods. Moist clay soils generally yield much lower results than dry sandy soils or rocky ground.

Why is it necessary to measure ground resistance after construction?

Completion of construction does not mean that requirements have been met. Two grounding systems may look identical, but the measured values can differ significantly. Measurement is the only way to know the system's current state.

Furthermore, earth resistance can gradually increase over time due to dry soil, oxidized grounding rods, or degraded connections. This is why large construction projects often undergo periodic inspections.

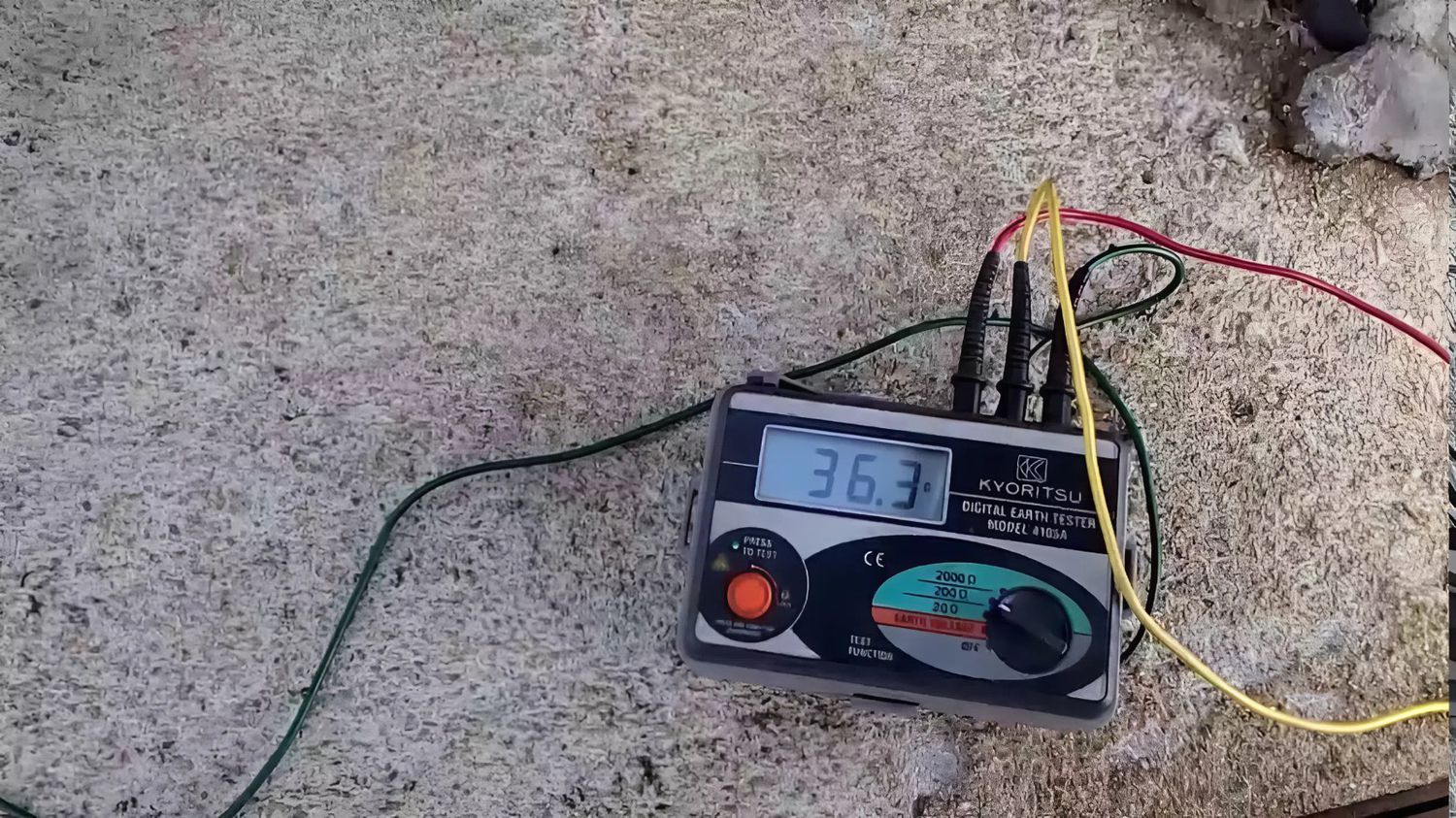

In the field, measuring instruments such as the Kyoritsu 4105A or Hioki FT3151 are widely used due to their fast operation and suitability for measuring both single piles and multi-pillar systems. For larger projects, the Hioki FT6031-50 allows measurements without disconnecting the connections, saving inspection time.

What is the appropriate resistance rating for a lightning protection system?

According to applicable standards, direct lightning protection systems are generally recommended to have a resistance level not exceeding 10 ohms. This is sufficient to dissipate lightning surges into the ground instead of propagating back into the building.

In areas with poor soil conditions such as rocky or dry sand foundations, the resistance may be higher. In such cases, additional grounding rods, increased embedment depth, or soil treatment may be necessary to reduce resistance.

- Low-voltage residential and industrial electrical systems

With commonly used voltages of 380V and 220V, requirements are usually stricter.

Houses and small workshops typically accept a voltage not exceeding 10 ohms. Systems with higher power or a concentration of electrical equipment require even lower voltages, usually not exceeding 4 ohms, to limit the risk of leakage current.

- Repeated grounding of the neutral point

In distribution lines, each repeated grounding point is typically required to not exceed 10 ohms. If geological conditions are difficult to handle, a higher level may be acceptable, but the number of grounding points must be increased to better disperse the current.

- Anti-static grounding

Fuel depots, chemical plants, or areas with flammable materials require extra attention to static electricity. For these systems, the grounding resistance is usually allowed to be higher, commonly below 100 ohms, as long as the charge does not accumulate over time.

- Common grounding for multiple systems

When power, telecommunications, and lightning protection share a single grounding system, the requirements become more stringent. A common level is not to exceed 1 ohm to avoid voltage differences between systems in case of a fault.

Ground resistance measuring devices are being used.

In practical grounding system testing, each measurement purpose requires a suitable type of equipment. The most common is the ground resistance meter, which uses the 3-pole method for stable and reliable results, and is chosen by many field engineers. For geological surveys, the 4-stake soil resistivity meter helps assess soil characteristics before construction.

For quick checks of an operating system, a ground resistance clamp meter offers convenience as it doesn't require disconnection. Additionally, some multimeters still integrate basic ground resistance measurement functionality, suitable for applications that don't require extremely high accuracy. Brands like Fluke, Hioki, and Kyoritsu are currently widely used in this category of equipment.