In residential, commercial or industrial environments, installation testing always plays a decisive role in ensuring the safety and reliability of the entire electrical system. With its sturdy structure and high durability, the 1670 Series allows engineers to evaluate the quality of installations in accordance with IEC/HD 60364-6 and regulations in each country. Fast measurement speed, on-site data processing capability and a set of inspection support tools significantly reduce recording time and increase accuracy in all stages of work.

Simplified interface, optimized for test preparation

The highlight of the new machine is the intelligent control interface that allows the organization of test data in a hierarchical tree form including customers, locations, electrical cabinets, circuits and each specific measurement point. Engineers can customize this structure directly on the machine's high-resolution touch screen or synchronize two-way with TruTest software.

During the working process, all information can be edited directly, helping to avoid errors when recording manually. The measurement tables clearly display each parameter and measurement position, helping engineers always make sure they are measuring the right point and the right data. Thanks to that, the test preparation time is significantly shortened, reducing the workload and focusing more on the actual assessment process.

Up to 30% faster test execution speed

In practice, electrical installation testing is often time-consuming due to the need to repeatedly perform setup tasks. This not only slows down progress but also leads to errors due to manual operations.

On the 1673 FC and 1674 FC, the Auto Test feature allows the entire test series to be run with just one button. The machine will provide visual connection instructions right on the screen, automatically compare the results to the established standards and notify whether they pass or fail. Automating the entire measurement series not only increases accuracy but also reduces the execution time by up to 30 percent compared to manual processes, helping engineers handle more items in the same working day.

Significantly reduce the volume of records and reports

The 1670 Series eliminates the need for engineers to re-enter data when they return to the office. Measurement results can be directly tied to each actual measurement point, eliminating the need for manual compilation. Engineers can preview records in the field using the instrument itself, on their phone, or via Fluke Connect.

TruTest software supports the creation of inspection certificates or acceptance reports in just a few steps. From data storage, form creation to exporting documents to customers, every operation is optimized so that engineers can complete inspection work within the same day. TruTest also supports the creation of certificates according to many popular European standards such as BS7671, DIN VDE 0100 600, ÖVE/ÖNORM E 8101, NIN/NIV, NEN3140 and many other international models.

PreTest function helps prevent errors in insulation measurement

On the 1674 FC model, Fluke equipped the Insulation PreTest function. The instrument will automatically detect if there is a device still connected on the line and immediately stop the insulation measurement, at the same time providing visual and audio warnings. This helps to avoid damage to peripheral equipment and prevent unfortunate errors that are common in manual insulation tests.

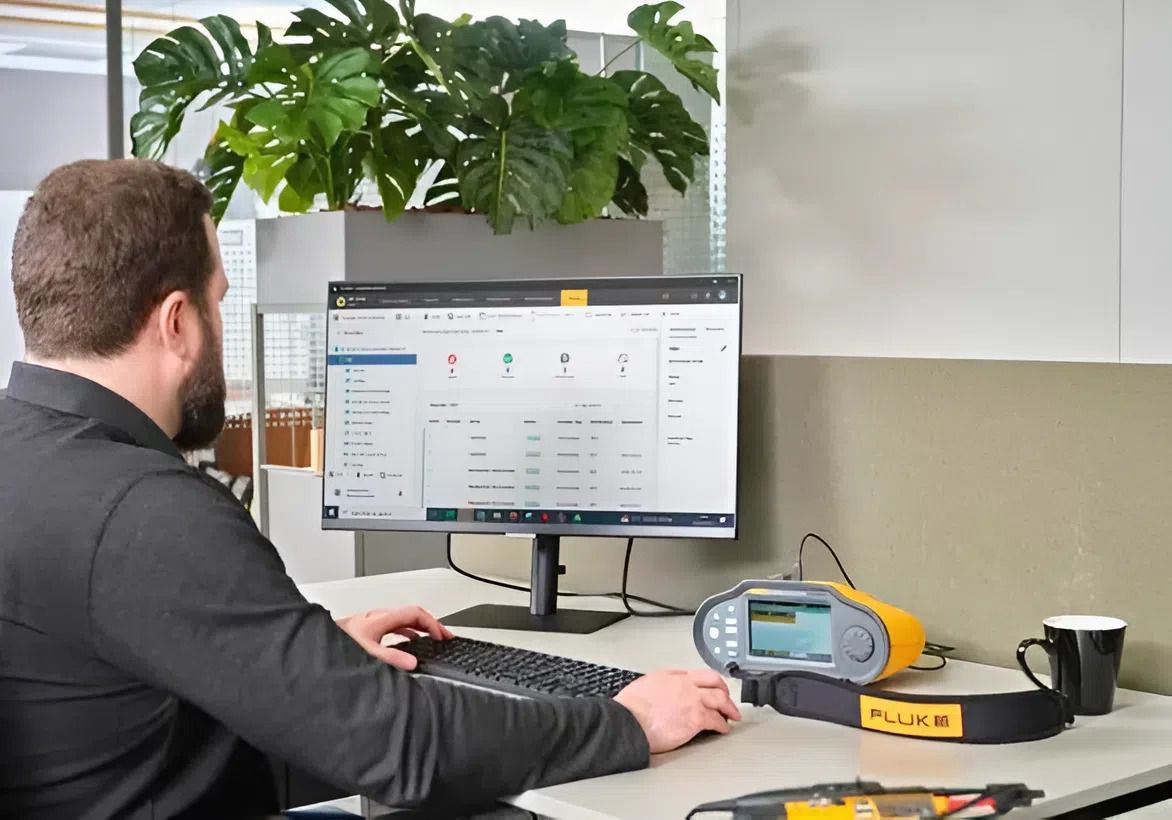

TruTest is at the heart of the 1670 Series ecosystem. The software allows data to be synced via USB C cable or via Fluke Connect. The intuitive interface, simple workflows and quick report generation make managing multiple customers, sites and projects a breeze.

TruTest also allows you to add your company logo, digitally sign and export certificates or reports in minutes. The intuitive dashboard allows you to track progress for each customer and each electrical system, helping engineers make faster and more accurate decisions.

Fluke Connect connectivity for seamless workflow

Synchronizing measurement data in the field eliminates manual recording. When testing scope needs to be expanded, devices such as the Fluke 369 FC Leakage Current Clamp or the Fluke 1630-2 FC Earth Resistance Clamp can be connected to feed data into the same reporting system, ensuring a more comprehensive assessment of electrical system health.

Flexible operational capabilities in practice

The 1670 Series is designed to adapt to real-world working environments. It weighs less than 1.6 kg, comes with a convenient strap, a large capacity Li-ion battery enough for a working day and a USB C charging port that supports fast charging. A dedicated carrying case helps protect the device when traveling or working in a construction environment.

In addition, there are a series of powerful supporting features such as fast loop measurement mode, insulation monitoring device test, surge protection test, voltage drop measurement, Z Max, zero adapter wire compensation, simultaneous reading of L N and PE voltage, comprehensive RCD test, loop test without wire change, 10 mA low current continuity test and high earth voltage warning via touch sensor.