直接联系认证专家

Stylus force - adjustable between 30 - 220 mgf (~0.3 - 2.2 mN) to remove ringing effect anddeliver better results on soft surfaces.

Annular surface measurements - measure aspheric mirrors with central hole and analyse using simplepart description and automated routine.

Dual surface measurements - measure both surfaces of a lens in a single run and analyse for form, radius and center thickness.

Automated motorised stages - increase flexibility with the addition of motorised Y-Axis and/or Rotary stages, coupled with a precision tilt and centre stage

Advanced error compensation - calculate and correct for x-offset, radius and form errors in a single run for diamond turned parts.

3D astigmatism - take multiple radial traces and analyse for astigmatism, accompanied by 3D map and Zernike coefficients.

Intelligent cresting - accurately identifies the part centre regardless of surface form allowing accurate measurements to be taken automatically.

Measurement start memory - allows repeat measurements to be taken without the need for re-cresting to lower cycle times and save time in production environment.

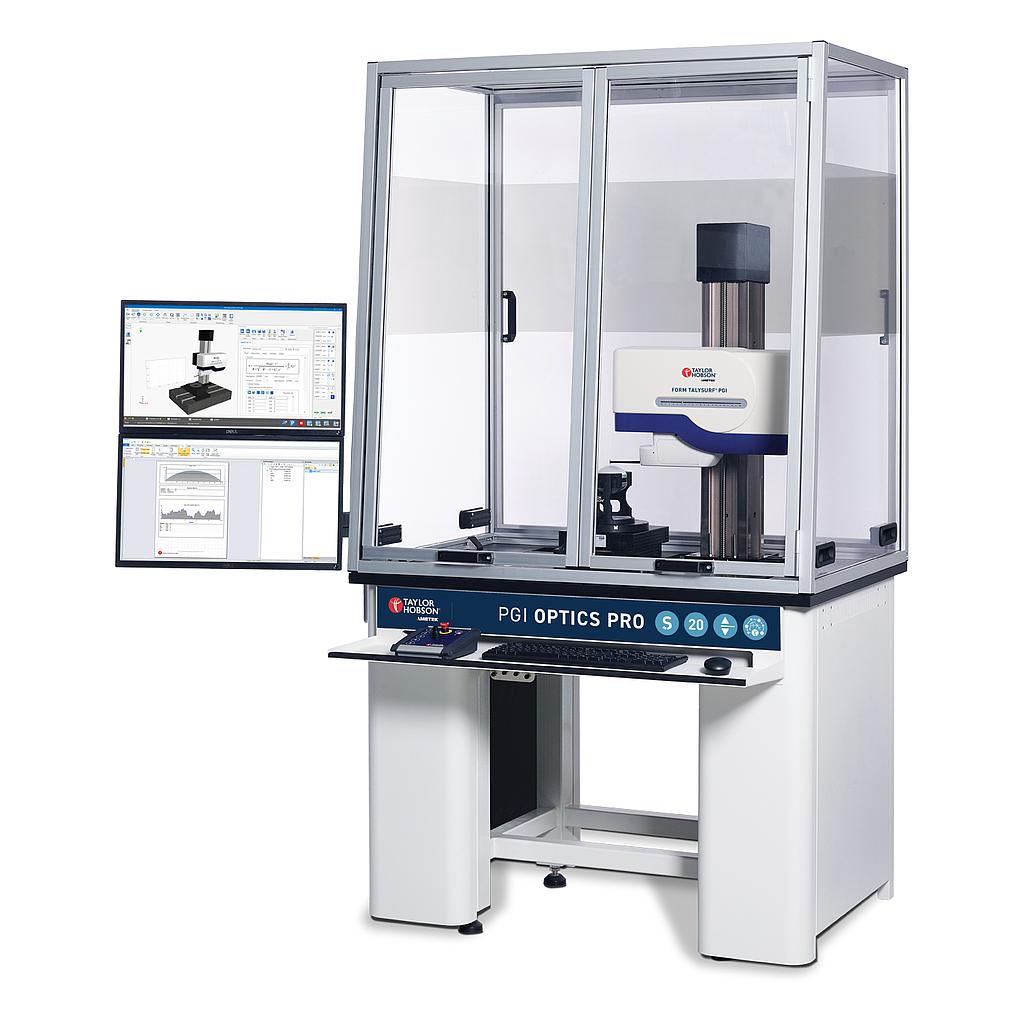

The Form Talysurf® PGI Optics PRO contact profilometer, measures surface form & radius of optical components, from a large diameter lens with large SAG to small plastic lenses.

Producing high accuracy measurements on spherical, aspherical, diffractive and fresnel lenses up to 300 mm diameter (single trace, no stitching). The system is capable of measuring both IR (infrared), visible substrates and mirror optics.

These capabilities make the Form Talysurf® PGI Optics PRO the backbone of optical manufacturing.

A fast, high accuracy measurement system for precision optics

Following its first release in 1984, the Form Talysurf® quickly became the number one choice for optics manufacturers measuring aspheric form error. Since then, we have installed thousands across the world, making the Form Talysurf® PGI a true industry standard.

Our patented PGI (Phase Grating Interferometer) technology enables you to measure large sags with short length styli for the highest accuracy measurements. These Taylor Hobson manufactured styli combine very high stiffness and low force, which delivers much greater accuracy and repeatability than comparable products.

Increase automation and consistency of the Form Talysurf® PGI Optics PRO with the addition of motorised Y and/or Rotary stages, coupled with a precision tilt and centre stage.

Fully automated, fast and accurate freeform optics measurement

The NEW Freeform module provides 3D raster measurement and analysis of freeform optics. Reduce cycle times with fully automated measurement routines and analysis of freeform surfaces.

The Freeform module can work with standard equations for common surfaces such as Toric, Bi-conic, Ellipsoid, A-Cylinder and Anamorphic asphere.

A benchmark for accuracy and versatility

Easy to program, fast and accurate

Designed for production environments

Powerful analysis tools to improve your capacity and capability

Time-saving software functions - One-click measurements

Measurement of large sag lenses without compromise

Automated software routines for repeatable high accuracy measurements

Powerful features with new PGI gauge

Low and adjustable stylus tip force for better performance on large sag parts and soft surfaces

Precision lift/lower for interrupted surfaces e.g. annular mirrors

Dual bias for top and bottom surface measurements

Low noise for more accurate measurements

High resolution for more data

Dedicated optical metrology analysis with Metrology 4.0 Software

In-depth asphero-diffractive and fresnel analysis

Rapid diamond tool setup: Unique solution for X-offset, radius and form error correction in one step

Astigmatism and trefoil: Multiple traces for 3D map generation and non-symmetric error analysis

Reverse engineering: One button to derived aspheric and diffractive coefficients

Datasheet