Get exclusive volume discounts, bulk pricing updates, and new product alerts delivered directly to your inbox.

By subscribing, you agree to our Terms of Service and Privacy Policy.

Direct access to our certified experts

Get exclusive volume discounts, bulk pricing updates, and new product alerts delivered directly to your inbox.

By subscribing, you agree to our Terms of Service and Privacy Policy.

Direct access to our certified experts

Specification

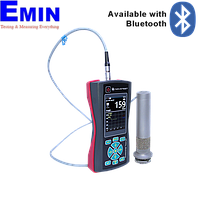

Data printout: with bluetooth printer

Main test parameter: HV

Convertible parameters: HRA, HRB, HRC, HBW, HS, MPa

Measurement range: 50~1599HV, 20~68HRC, 85~650HB, 41~100HRB

61~85.6HRA, 34.2~97.3HS, 255~2180MPa

Resolution: 1HV, 0.1HRA, 0.1HRB, 0.1HRC, 1HB, 0.1HS, 1MPa

Accuracy: ±4%HV, ±4%HB, ±1.5HR

Calibration method:

Normal material: one-point calibration

Special materials: multi-point calibration

Operating temperature: -10°C ~ 40°C

Power supply: built-in rechargeable lithium battery (for 10 hours working)

Dimension of main unit: 190×82×30mm

Dimension of probe: 150xØ22mm

Weight: 540g

Standard delivery

Main unit: 1pc

19.6N manual probe: 1pc

Bluetooth printer: 1pc

charger: 1pc

USB cable: 1pc

Randomized standard hardness block: 1pc

- Small size, light weight, portable, convenient for on-line measurement and can be used to measure large workpieces

- Support 360°measurement, fast test speed, the fastest results in 1 second

- Standard Vickers indentation, small test indentation and low damage to the workpiece

- 100 measurement data sets and 10 calibration data sets can be stored

- Large display, directly shows the current measured value, maximum value, minimum value, average value and unit conversion value

- For unspecified conversion tables and unknown materials, multi-point calibration on any hardness scale you can choose to eliminate of systematic errors due to conversion tables

- According to DIN 50159, ASTM A1038 standards

Applications:

1. Hardness measurement of flange edges and gearoot stampings, gears and gear grooves with hardened die sheet surfaces, taper sections

2. Hardness measurement of shafts and thin-walled pipes and vessels

3. Hardness measurement of thin plated layers, wheels, turbine rotors and welded parts

4. Measurement of the depth of a certain hole diameter deep holes, curvature of the larger dents and convex marks, irregular planes

5. Covering the majority of hardness measurement of industrial production of ferrous metals, non-ferrous metals and their alloys

Datasheet