Get exclusive volume discounts, bulk pricing updates, and new product alerts delivered directly to your inbox.

By subscribing, you agree to our Terms of Service and Privacy Policy.

Direct access to our certified experts

Get exclusive volume discounts, bulk pricing updates, and new product alerts delivered directly to your inbox.

By subscribing, you agree to our Terms of Service and Privacy Policy.

Direct access to our certified experts

Measuring indenter: Diamond indenter for Micro-Vickers (facing-to- surface angle of 136˚)

Test load and control no. CE making complied models are required to add (CE) with control no.: Approx 1kgf (roughly 10N)

Measuring range

Rockwell hardness: 10.0~70.0 HRC

Vickers hardness: 100~999 HV

Shore hardness: 20.0~99.9 HS

Brinell hardness: 85~550 HBW

Reproducibility

HRC: ±1.0HRC. HV: ±(3%rdg)HV, HS: ±1.0HS, HBW: ±(3%rdg)HBW

Applicable test materials: With steel as the principle material, other metallic materials may also be measured by calibrating against a standard hardness test block.

Display of measured values: Digital display (LCD, 4 digits) with EL backlight

Data memory: 2000 pieces

Digital display units: 1HV, 0.1HRC, 0.1HS, 1HBW, 1N/mm2 (tensile strength)

Allowable operating temperature: 0~50ºC

Power source: AC adapter(100~240V) or lithium ion rechargeable battery operatable for continuous 8 hours (with new battery)

Continious operating hours: 5 hours when featuring a rechargeable BL; 8 hours without BL

*BL= backlight

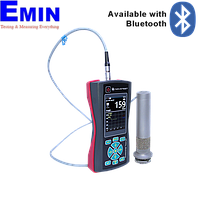

Dimensions: Display unit 97mm(W) X 172mm(H) X 50mm(D),

Probe diameter: 50mm, length: 170.5mm

Weight

Display unit: approx. 400g (including battery),

Probe and cable: approx. 430g

Carrying case dimensions: 389mm(W) x 132mm(H) x 200mm(D)

Alarm: Alarm (buzzer sound)

Output: RS-232C output used for data transmission or printing

Frequency: Motorized / manual switchover type approx 69~71kHz

Conversion: Compliant with SAE J417, JIS в 7731