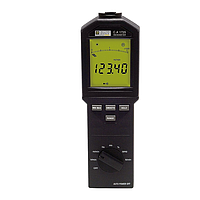

Tachometer

Have you ever been curious about the rotational speed of the objects around you? Rotational speed is not just an abstract concept, but also an important parameter in many industries and applications. A rotational speed meter is a device used to measure and monitor the rotational speed of objects, ranging from industrial machinery to electronic devices, vehicles, and even scientific research.

Why is a Tachometer meter important?

The rotational speed of an object can provide important information about operating performance and lifespan, as well as serve as a way to control the working process of machinery and equipment. In industrial applications, measuring rotational speed can help determine production output, inspect product quality, and prevent equipment failure. This helps save time and energy while optimizing production processes.

Rotational speed meters typically use a range of sensors placed on the surface of the object along with a controller to collect and process data. These sensors can measure rotational speed through scanning, frequency analysis, or by tracking factors such as light intensity. The data is then processed and displayed to the user via a screen or computer interface.

A rotational speed meter is a device designed to measure and monitor the rotational speed of an object over a specific period of time. It can measure rotational speed in different units such as revolutions per minute (RPM), revolutions per second (RPS), or radians per second (rad/s). Rotational speed meters can operate in various environments and are applied across many industries.

Applications of rotational speed meters

Rotational speed meters are widely used in industries such as manufacturing, automotive, aviation, pharmaceuticals, and many other fields. Below are some key applications of rotational speed meters:

Checking the performance and lifespan of industrial machinery

Measuring the rotational speed of engines and components in automobiles

Monitoring the rotational speed of propellers and blades in the aviation industry

Measuring shaft rotational speed in pharmaceutical technology

Researching and analyzing rotational speed in scientific fields

How to choose a rotational speed meter

Before selecting a rotational speed meter, you need to consider several factors to ensure the device suits your needs and applications. Below are some important factors to consider:

The measurement speed range is an important factor to consider. You need to determine the required speed range and select a rotational speed meter with a measurement range suitable for your needs. This ensures accurate and reliable rotational speed measurements.

Accuracy and resolution are other important factors of a rotational speed meter. You should check the accuracy and resolution of the device before purchasing. This ensures you can measure rotational speed with the desired level of precision and detail.

The size and portability of the rotational speed meter should also be considered. You need to ensure the device size fits your working space. If you need to move the rotational speed meter between different locations, make sure it is lightweight and easy to transport.

How to use a rotational speed meter

Rotational speed meters can be used across various industries and applications. Below are the basic steps to use a rotational speed meter:

Before using the rotational speed meter, you need to prepare the device according to the manufacturer’s instructions. This includes charging the battery (if required), connecting sensors, and ensuring the meter is placed in a suitable position.

Depending on the application, you need to place the sensors on the object whose rotational speed you want to measure. Make sure the sensors are positioned accurately and securely to ensure precise speed readings.

After preparing the meter and positioning the sensors, you can start measuring the speed by pressing the start button on the device. The meter will begin collecting data and display the results on the screen or interface.

After measuring the speed, you need to evaluate the results and analyze the information. Use analytical tools and compare the results with your targets or required specifications. This helps you make decisions regarding the performance and lifespan of machinery and equipment.

Frequently asked questions about rotational speed meters

1. What is a rotational speed meter?

A rotational speed meter is a device used to measure the rotational speed of an object. It can be applied in various fields such as industry, engineering, and research.

2. Why do we need to use a rotational speed meter?

A rotational speed meter helps us accurately determine and measure the rotational speed of an object. This is very useful for checking the operating efficiency of machinery, analyzing motion, measuring changes in objects over time, and many other applications.

3. How does a rotational speed meter work?

A rotational speed meter typically uses sensors or counters to measure the number of rotations or shaft revolutions within a specific unit of time, from which the rotational speed is calculated.

4. What types of rotational speed meters are available?

There are several commonly used types of rotational speed meters, including:

Get exclusive volume discounts, bulk pricing updates, and new product alerts delivered directly to your inbox.

By subscribing, you agree to our Terms of Service and Privacy Policy.

Direct access to our certified experts