So what is the difference between a VFL and an OTDR? When should each be used for the fastest and most targeted fault detection?

Visual Fault Locator (VFL)

VFL (Visual Fault Locator) is a compact device, popular in fiber optic cable testing and maintenance work. This device is easy to use, convenient to carry and operates on the principle of emitting red light with a wavelength of about 650nm from the connector, transmitted along the optical fiber. Users can adjust the continuous or flashing light mode depending on the testing needs.

The detection efficiency of VFL depends on the power of the light source, the most common is the Tribrer BML208-V10 optical pen with a power of about 10mW, allowing to detect errors on optical fibers at a distance of up to 10km. In addition, there are more powerful versions, supporting a range of 15km, 20km or 30km. When the emitted light is interrupted or shines at an abnormal position on the optical fiber, that is the point where the error or break occurs.

You can refer to the products at: Danh mục Thiết bị định vị lỗi quang EMIN

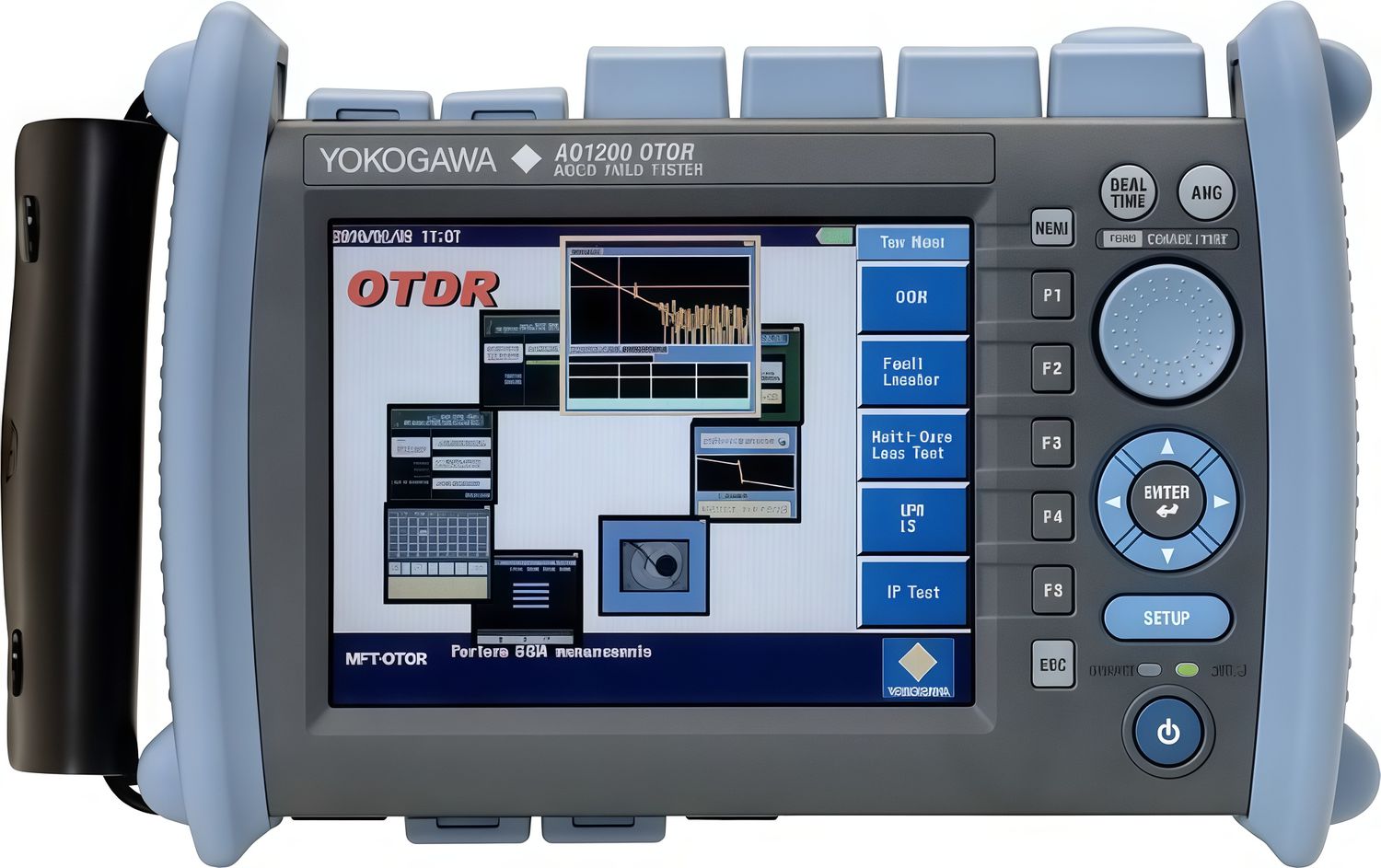

Optical OTDR, optical reflectometer for tracing errors on cable lines

OTDR (Optical Time Domain Reflectometer) is used to re-read the entire “lifecycle” of the optical fiber: from the starting point, the connection point, the bend to the broken section. All errors are displayed in the form of light reflection graphs, which the installer can see which section has problems just by looking at it.

The operating mechanism is based on emitting a light pulse into the fiber core and collecting the reflected light. Through the amplitude and response time, the OTDR accurately determines the distance to the location of fiber loss or breakage.

When measuring, the operator can choose the wavelength according to the type of cable in use: 850/1300 nm for multi-mode cable or 1310/1490/1550/1625 nm for single-mode cable. The measurement range depends on the dynamic range and the set pulse width.

OTDR is often used during the acceptance or maintenance phase of systems with many joints, where it is necessary to check the entire line without having to remove the cable in sections.

Should use VFL or OTDR in each situation?

Both serve the purpose of fault detection, but each has its own role.

VFL is suitable for quickly identifying breaks or breaks on short lines, bare cables, optical distribution boxes, or in narrow operating environments. The technician only needs to turn on the red light source and observe directly, without having to operate on the screen or analyze the data.

OTDR is used when it is necessary to survey the entire route or localize faults on buried cables, backbone cables or multi-point systems. However, in short sections of a few dozen meters, OTDR has limitations in reading the start and end points, the feedback signal is too close for the machine to recognize the change. Therefore, in practice, technicians often combine both: VFL for quick visual inspection, OTDR for depth measurement and report saving.