The device simultaneously displays air temperature, humidity, dew point, surface temperature and Delta T difference to assess the safety of the surface at each time. This is a key factor to limit the risk of condensation causing peeling or spreading of the coating after completion.

Monitor dew point and evaluate surfaces using direct measurement data

The DPM LAB Dew Point Meter continuously collects environmental parameters, from which the dew point and Delta T difference are calculated to determine the risk of condensation. As the surface approaches the dew point, the coating is more likely to lose adhesion and develop defects. Technicians can rely on Delta T to decide the appropriate application time.

The bright display of the NOVOTEST DPM LAB supports reading data in sunlight or in areas with strong reflections. The user can choose to display each parameter in large format or view all parameters on one interface, suitable for quickly checking many consecutive locations. Evaluating the coating application conditions becomes more intuitive, especially in outdoor areas or newly cleaned surfaces.

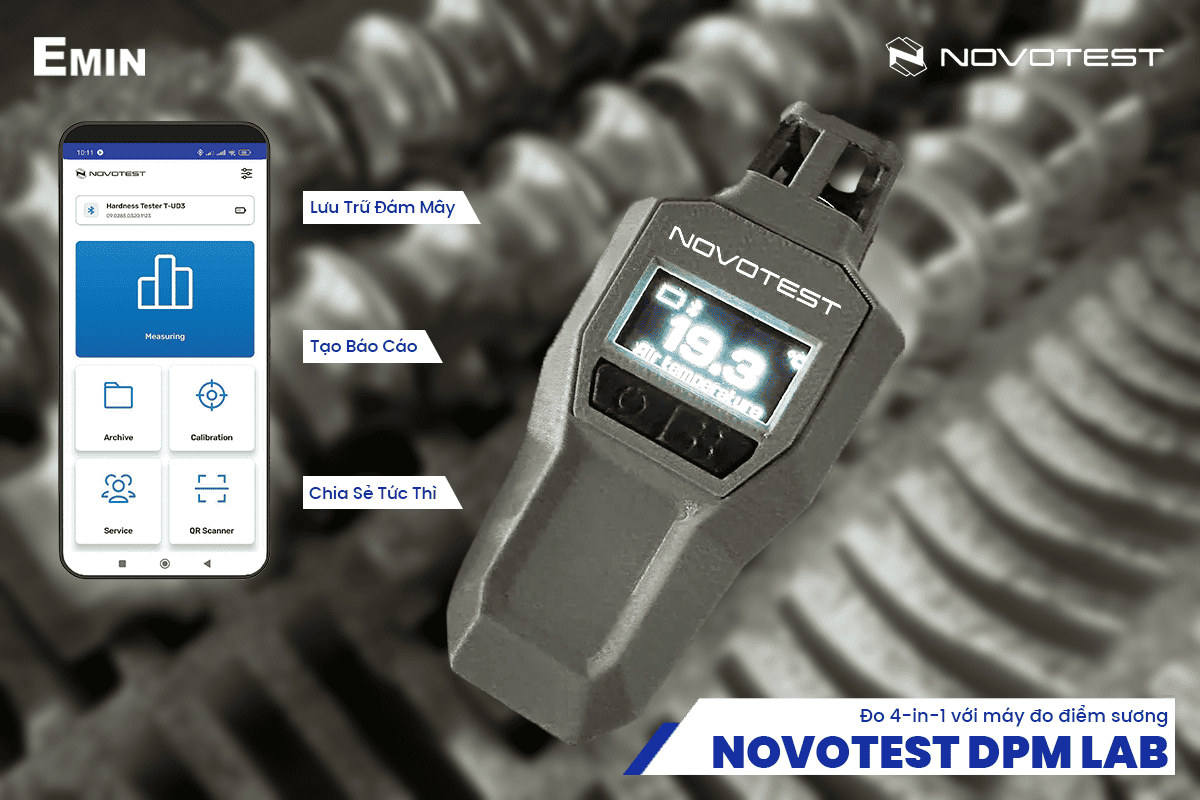

NOVOTEST Lab App for measurement management and construction reporting

NOVOTEST DPM LAB is at its best when combined with the NOVOTEST Lab App. The app allows you to record your measurements with photos and videos, create automatic reports, and synchronize data to the cloud. Each measurement value can be annotated with voice, image, or video to clearly describe the location or surface condition.

In projects with multiple construction teams, dew point meter data is easily shared with QA or site commanders via a communication application. Measurement history by area helps control progress and compare environmental conditions in previous shifts. When retrieval is needed, technicians can simply open the archived data without having to manually summarize.

The voice reading feature is useful when working in dark spaces or when wearing gloves. Measurement management becomes consistent, especially for projects that require transparent reporting of environmental conditions before painting or coating surfaces.

Site-appropriate design and flexible operation

The body of the DPM LAB is easy to hold and suitable for continuous operation on large surfaces. The device uses AAA batteries, convenient to carry spares and ensure operation for a full shift. The screen has high brightness, making data readable even in bright sunlight.

The USB C port is used for software updates and checking the device during maintenance. These factors help the dew point meter operate stably in industrial environments, where conditions fluctuate greatly and require the instrument to respond quickly when moving between multiple areas.

New sensor measures quickly and is suitable for many types of surfaces

The DPM LAB version uses a new generation of temperature and humidity sensors that register environmental changes more quickly. This is important when the operator is between a hot work area and a cold windy area or when inspecting outdoor construction sites.

Infrared surface temperature probes are fast-responsive and less dependent on the reflectivity of the material. Technicians can measure freshly cleaned steel, primer-coated materials, or low-gloss surfaces and still receive stable readings. When checking the condition of coatings, more accuracy is achieved, especially in projects requiring strict quality control.