The L*a*b* color model describes color based on how the human eye perceives it, helping to ensure that color is reproduced consistently across display devices and across different manufacturing processes. Understanding the principles of Lab colorimetry helps engineers and manufacturers minimize color variation, optimize Quality Control testing processes, and ensure consistency across production and display products.

What is the L*a*b* color system?

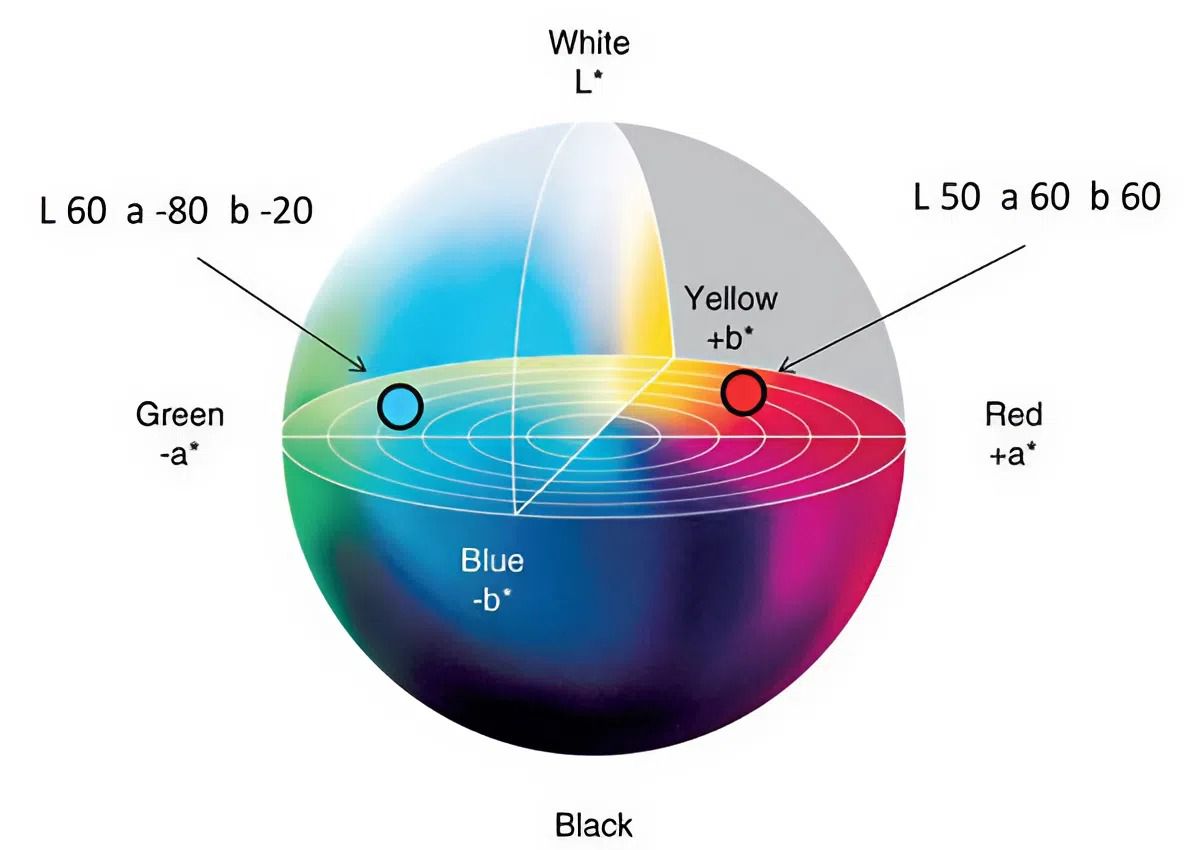

The L*a*b* color model is a color model that was developed to maintain color consistency across devices and accurately reflect how the human eye perceives color. Color in this system is described through three parameters: L represents brightness, a represents the degree of transition between red and green, and b represents the degree of transition between yellow and blue. In practice, color testing and analysis, this system is often denoted as L*a*b*.

The CIE L*a*b* color space was introduced in 1976 by the Commission Internationale d’Eclairage (CIE), building on the work of Hunter Lab. The unique feature of CIE L*a*b* is that it is device independent, meaning that the same color can be accurately reproduced and compared across different display systems or technologies. It is often used as a reference standard when converting between color spaces such as RGB and CMYK.

Due to its ability to accurately and objectively describe color, it is widely used in fields such as printing, coatings, product design, materials and quality control. The use of L*a*b* helps to ensure that color is represented faithfully, consistently and reliably under all display conditions.

Working principle of L*a*b* colorimetric method

After understanding the L*a*b* color system, the next step is to understand the operating principle of the colorimetric method. This is the basis for operators to perform color testing and comparison accurately, ensuring reliability in quality control processes.

The L*a*b* colorimetric method determines and compares color based on the principle of simulating the way the human eye perceives light. During the measurement, a device such as a colorimeter or spectrophotometer will shine a standard light source onto the sample surface. The reflected light is collected by the sensor and analyzed for each wavelength in the visible range from 380 to 780 nm. This data indicates the intensity of the sample's reflection in each color region, thereby accurately reflecting the optical properties of the material.

From the obtained reflectance spectrum, the device calculates the X, Y, Z values according to CIE standards - these are intermediate parameters representing color in three-dimensional space. Then, these values are converted to the L, a, b coordinate system as follows:

L*: represents brightness, values from 0 (black) to 100 (white).

a*: represents the color axis from green (negative value) to red (positive value).

b*: represents the color axis from blue (negative value) to yellow (positive value).

When comparing two samples, the device will calculate the deviation values ΔL, Δa, Δb and the combined value ΔE, in which:

ΔL: represents the difference in brightness. A large ΔL value indicates a brighter sample, a small ΔL indicates a darker sample.

Δa: represents the difference between red and green. A positive Δa is inclined towards red, a negative Δa is inclined towards green.

Δb: represents the difference between yellow and blue. A positive Δb is inclined towards yellow, a negative Δb is inclined towards blue.

The combined value ΔE represents the overall color difference between the measured sample and the standard. The smaller the ΔE, the more similar the two colors are. If it exceeds the allowable limit, the operating engineer will readjust the color matching or processing to meet the standard.

The L*a*b* color measurement method is widely used in printing, coating, textile dyeing, plastics, construction materials and electronic component manufacturing, where high color uniformity is required between product batches. Some popular devices using the L*a*b* measurement system include the CS-Series or modern color spectrophotometers that meet CIE standards.

Advantages and disadvantages of the CIE L*a*b* colorimetric method

The CIE L*a*b* colorimetric method is highly regarded for its ability to describe and test colors with outstanding accuracy. However, like other measurement methods, it has certain limitations that need to be noted when applied in production and quality control practices.

Advantage:

- Measurements are based on optical parameters, completely eliminating the subjective perception of the observer. Thanks to that, the results can be directly compared between different devices and measurements.

- The L*a*b* color system covers almost the entire color range that the human eye can perceive, helping to describe and reproduce colors accurately, especially useful in industries that require strict color control such as printing, painting, dyeing or material production.

- The values of ΔL, Δa, Δb and ΔE allow the operator to immediately recognize the trend of color deviation, thereby making timely adjustments to ensure the color meets the standard.

- The L*a*b* system is often used as an intermediary when converting between RGB and CMYK, helping to limit color deviation during printing and display.

- The independent L, a, b axes allow separate adjustment of brightness and hue, providing high flexibility in color calibration and processing.

Disadvantages:

- Requires the use of a high-precision colorimeter or spectrophotometer. The investment, calibration and maintenance costs are relatively high.

- The results may be affected by the light source, the angle of illumination, the type of surface or the gloss of the sample. Therefore, a standardized measurement procedure is required.

- The operator must clearly understand the meaning and relationship between the L*, a*, b* values to correctly evaluate the color deviation trend.

- Different measuring instruments may have small differences, so periodic calibration is required to maintain the reliability of the measurement results.

In general, the CIE L*a*b* colorimetric method is a widely applied standard in modern industry due to its high accuracy, systematicity and quantitative ability, although it still requires strict compliance with operating and calibration procedures to achieve stable results.