With casting, once you have the code, everything else is faster. Once you produce a product, the design is almost fixed. This method is suitable when you need a large quantity, consistency, and low cost. However, changing the weight or adjusting the dimensions is not feasible. Every time you want to make a small change, it involves fertilizer, cost, and time.

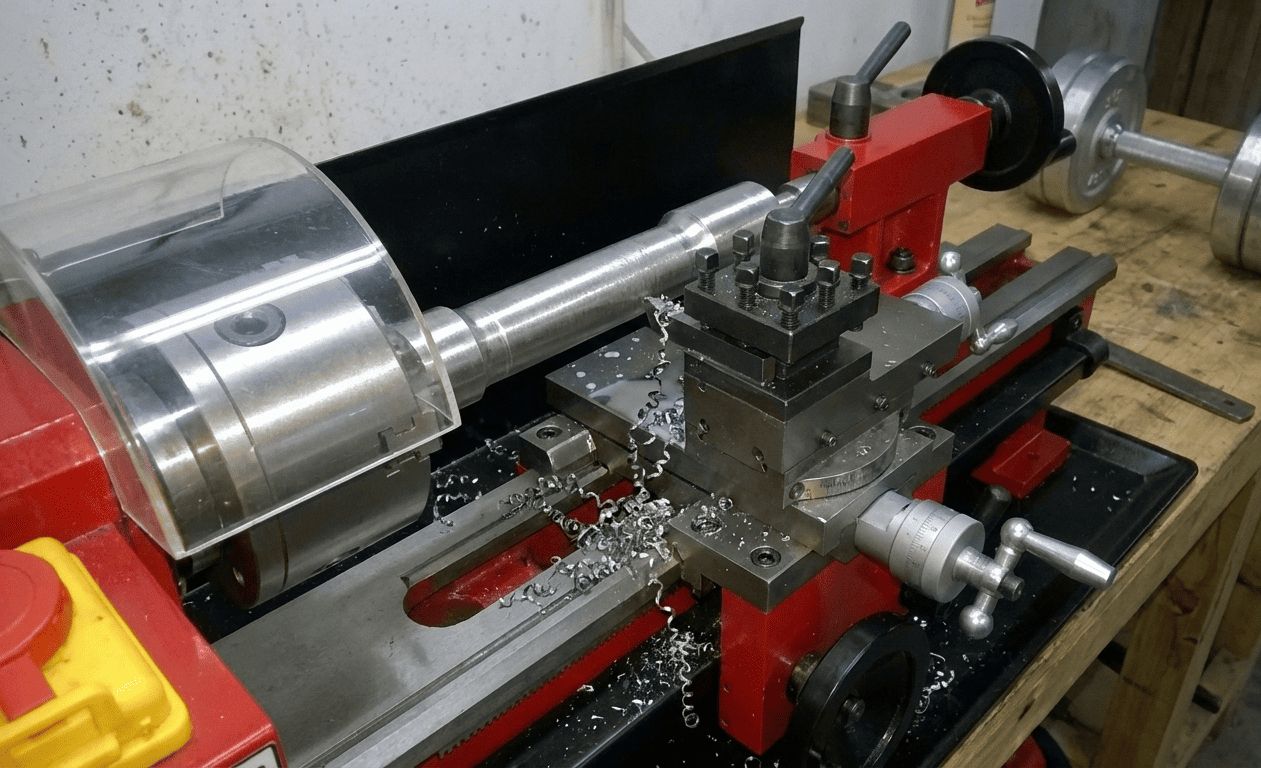

Turning dumbbells is more convenient in that respect. Starting from a round blank, the craftsman controls each cut. To make them heavier or lighter, they simply adjust the length or diameter. The thickness of the handle can also be adjusted directly on the machine. Each pair of dumbbells may be slightly different, but they are exactly what the user needs.

The feel in the hand is the most noticeable difference. Dumbbells turned from solid blanks feel very substantial and solid in the hand. Those who have trained for a long time will notice this difference, especially when holding the dumbbells for extended periods or performing exercises that require wrist stability.

Ultimately, casting is suitable for mass production, while machining is better suited for precision work and specific needs. Which method a workshop chooses usually depends on its objectives.

Why do many machine shops choose to machine dumbbells instead of ordering them ready-made?

Many workshops start very simply. Some ask gym-goers for help, others try it out for fun when their machines are idle. After a while, they realize this is a fairly easy business model to operate.

The first advantage is independence. No need to wait for orders, no dependence on external sources. If you have the raw materials, the machines, and the workers, you can start immediately. You only produce what you need, without worrying about inventory.

Another advantage is utilizing the machine's downtime. During periods without large orders, a few pairs of weights can be conveniently made, keeping the machine running while also creating additional products, eliminating pressure to meet deadlines or urgent deliveries.

Customer demand also contributes to this trend. Many people prefer custom-made weights, precisely the weight they need and the familiar grip size. Ready-made products struggle to fully meet these requirements.

For small workshops or general-purpose workshops, making dumbbells is a manageable task. It doesn't require significant additional investment; the important thing is to work carefully and consistently, ensuring that the products sell as soon as they are produced.

The most suitable material for machining dumbbells in a practical workshop setting.

Regarding materials, it's not too complicated; it's mainly about choosing something familiar and easy to control.

Carbon steel is the most commonly used. The blanks are readily available, the price is acceptable, the machining is stable, and the cutting edge is consistent. The finished product is heavy, solid, and impact-resistant. For most workshops, this is a safe and low-risk choice.

Cast iron is also frequently used, especially when the workshop has blanks readily available. Cast iron feels heavy quickly, and the finished product is fairly compact. A point to note is that the edge is prone to chipping if subjected to strong impact, so careful attention to cutting parameters and surface finish is necessary during machining.

Aluminum or aluminum alloys are less commonly chosen for regular weightlifting dumbbells. They are lightweight and don't feel like traditional dumbbells. They are usually only used as models or for lightweight recovery weights.

Ultimately, it all comes down to a familiar factor: a stable blank, a familiar material, and ease of machining that doesn't pose difficulties for the worker are what should be prioritized.

How does the size of the blank affect the grip feel during practice?

Many beginners only focus on the weight in kilograms. Experienced exercisers, however, pay more attention to the shape of the dumbbell.

Two dumbbells of the same weight but different diameters feel very different. A large but thin dumbbell can quickly tire the wrists. A smaller but longer dumbbell feels more compact and easier to control.

The grip also has a significant impact. A grip that's too large tires quickly, while one that's too small slips easily, especially when sweating. A diameter that's just right for the fingers to comfortably grip provides the most comfortable feel.

The advantage of machined weights is that they can be adjusted precisely. Just a few millimeter changes can make a huge difference. This is also why many people value machined weights more than ready-made ones.

Can a basic lathe in the workshop handle the machining of dumbbells? Suggestions for lathes at EMIN.

Machining dumbbells doesn't require overly heavy machinery. A standard lathe with decent rigidity and a smoothly running spindle is sufficient for the job. A secure workpiece clamp and a skilled operator remain the deciding factors.

Workshops already familiar with machining shafts, bushings, and round parts will have little difficulty transitioning to dumbbell machining. Just pay more attention to the outer surface, as that's the part users handle directly every day.

If your workshop is planning to upgrade or purchase additional machines, prioritize models that are stable, easy to maintain, and have readily available spare parts. EMIN offers many metal lathe models suitable for small and medium-sized workshops, focusing on durability and long-term operation, making them ideal for simple round machining tasks like dumbbells.

A very popular example for small workshops is the Sieg C2 mini lathe, officially distributed by EMIN. This model runs stably, is easy to operate, suitable for basic round parts, and is also a good option for trying your hand at machining small dumbbells.