HUATEC RHL30 便携式硬度计(D型)

制造商: HUATEC Model: RHL30 来源: China - 联系

Specifications of hardness tester

Hardness scale: HL, HB, HRB, HRC, HRA, HV, HS

Memory: 48~600 groups (impact times: 32~1)

Measuring range: HLD(170~960) See below table 1 and table 2

Accuracy: ±6HLD (760±30HLD) error of displayed value

repeatability of displayed value: 6HLD (760±30HLD)

Standard Impact Device: D

Optional Impact Devices: DC/D+15/G/C/DL

Max. Workpiece Hardness: 996HV (For Impact Devices D/DC/DL/D+15/C)

646HB(For Impact Device G)

Min. Radius of Workpiece (convex/concave) Rmin = 50mm (with special support ring Rmin= 10mm)

Min. Workpiece weight: 2~5kg on stable support

0.05~2kg with compact coupling

Min. Workpiece thickness: 5mm (Impact Devices D/DC/DL/D+15)

1mm (Impact Device C)

10mm (Impact Device G)

Min. thickness of hardened surface: 0.8mm

Power: Rechargeable Li lon battery 3.7V/600mA, 4 years life time

Continuous Working time: approx. 100 h (no back light off)

Charging time: 2-3.5 h

Operating temperature: 0~40 oC

Relative humidity: ≤90%

Overall dimensions: 152×84×34mm (main unit)

Weight: 0.3kg (main unit)

Standard delivery of portable leeb hardness tester RHL10

●Main unit

●Impact Device type D

●Test block with HLD value

●Charger

●Nylon brush

●Small supporting ring

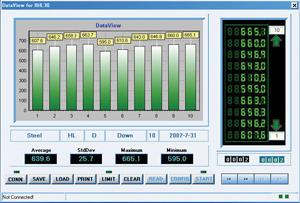

●DataView Software

●USB Communication cable

●Calibration Certificate

●Instruction manual

●Warranty card

●Carrying case

●Normal and special type support rings (14pcs)

|

Material

|

Hardness method

|

Impact device

|

|||||

|

D/DC

|

D+15

|

C

|

G

|

E

|

DL

|

||

|

Steel and cast steel

|

HRC

|

17.9~68.5

|

19.3~67.9

|

20.0~69.5

|

|

22.4~70.7

|

20.6~68.2

|

|

HRB

|

59.6~99.6

|

|

|

47.7~99.9

|

|

37.0~99.9

|

|

|

HRA

|

59.1~85.8

|

|

|

|

61.7~88.0

|

|

|

|

HB

|

127~651

|

80~638

|

80~683

|

90~646

|

83~663

|

81~646

|

|

|

HV

|

83~976

|

80~937

|

80~996

|

|

84~1042

|

80~950

|

|

|

HS

|

32.2~99.5

|

33.3~99.3

|

31.8~102.1

|

|

35.8~102.6

|

30.6~96.8

|

|

|

Hammered steel

|

HB

|

143~650

|

|

|

|

|

|

|

Cold work tool steel

|

HRC

|

20.4~67.1

|

19.8~68.2

|

20.7~68.2

|

|

22.6~70.2

|

|

|

HV

|

80~898

|

80~935

|

100~941

|

|

82~1009

|

|

|

|

Stainless steel

|

HRB

|

46.5~101.7

|

|

|

|

|

|

|

HB

|

85~655

|

|

|

|

|

|

|

|

HV

|

85~802

|

|

|

|

|

|

|

|

Gray cast iron

|

HRC

|

|

|

|

|

|

|

|

HB

|

93~334

|

|

|

92~326

|

|

|

|

|

HV

|

|

|

|

|

|

|

|

|

Nodular cast iron

|

HRC

|

|

|

|

|

|

|

|

HB

|

131~387

|

|

|

127~364

|

|

|

|

|

HV

|

|

|

|

|

|

|

|

|

Cast aluminum

alloys

|

HB

|

19~164

|

|

23~210

|

32~168

|

|

|

|

HRB

|

23.8~84.6

|

|

22.7~85.0

|

23.8~85.5

|

|

|

|

|

Brass(copper-zinc alloys)

|

HB

|

40~173

|

|

|

|

|

|

|

HRB

|

13.5~95.3

|

|

|

|

|

|

|

|

Bronze (copper-aluminum/copper-tin alloys)

|

HB

|

60~290

|

|

|

|

|

|

|

Wrought copper

alloys

|

HB

|

45~315

|

|

|

|

|

|

|

No.

|

Material

|

HLD

|

Strength σb(Mpa)

|

|

1

|

Mild steel

|

350~522

|

374~780

|

|

2

|

High-carbon steel

|

500~710

|

737~1670

|

|

3

|

Cr steel

|

500~730

|

707~1829

|

|

4

|

Cr-V steel

|

500~750

|

704~1980

|

|

5

|

Cr-Ni steel

|

500~750

|

763~2007

|

|

6

|

Cr-Mo steel

|

500~738

|

721~1875

|

|

7

|

Cr-Ni-Mo steel

|

540~738

|

844~1933

|

|

8

|

Cr-Mn-Si steel

|

500~750

|

755~1993

|

|

9

|

Super strength steel

|

630~800

|

1180~2652

|

|

10

|

Stainless steel

|

500~710

|

703~1676

|

PC Software sample

- 质量承诺

- 正品保修

- 送货到家

- 交易简单化