Soldering Stations ASAKI

Soldering stations for electronic assembly and repair

Electronic component soldering requires stable heat at the soldering tip. Low heat makes solder difficult to adhere. Excessive heat damages components and causes joint separation. Soldering stations are used to maintain an appropriate temperature throughout the operation, helping create neat solder joints with even adhesion and good electrical conductivity.

Compared with standalone soldering irons, soldering stations allow temperature adjustment and stable heat retention, making them suitable for repetitive soldering tasks or circuit boards with multiple components.

Simple explanation of what a soldering station is

A soldering station, also known as a soldering unit, is simply used to heat the soldering tip to a preset temperature to melt solder. Molten solder bonds electronic components, wires, or small metal parts to the surface of a circuit board.

Temperature control helps solder joints adhere firmly, reduces peeling, and lowers the risk of component damage during operation.

Soldering stations are commonly used for the following tasks:

- Repairing electronic circuit boards

- Assembling control boards

- Soldering wires in household electrical devices

- Fabrication and maintenance of industrial equipment

- Practice and teaching in electrical and electronic training

Classification of soldering stations

Based on temperature control methods, soldering stations are commonly divided into two groups.

Analog soldering stations

Analog soldering stations adjust temperature using a mechanical rotary knob. The device does not display a specific temperature, and stability remains at a basic level. Advantages of this type include simple structure, ease of use, and low failure rates.

Analog soldering stations are suitable for minor repairs, common soldering tasks, electrical and electronic students, or beginners learning soldering.

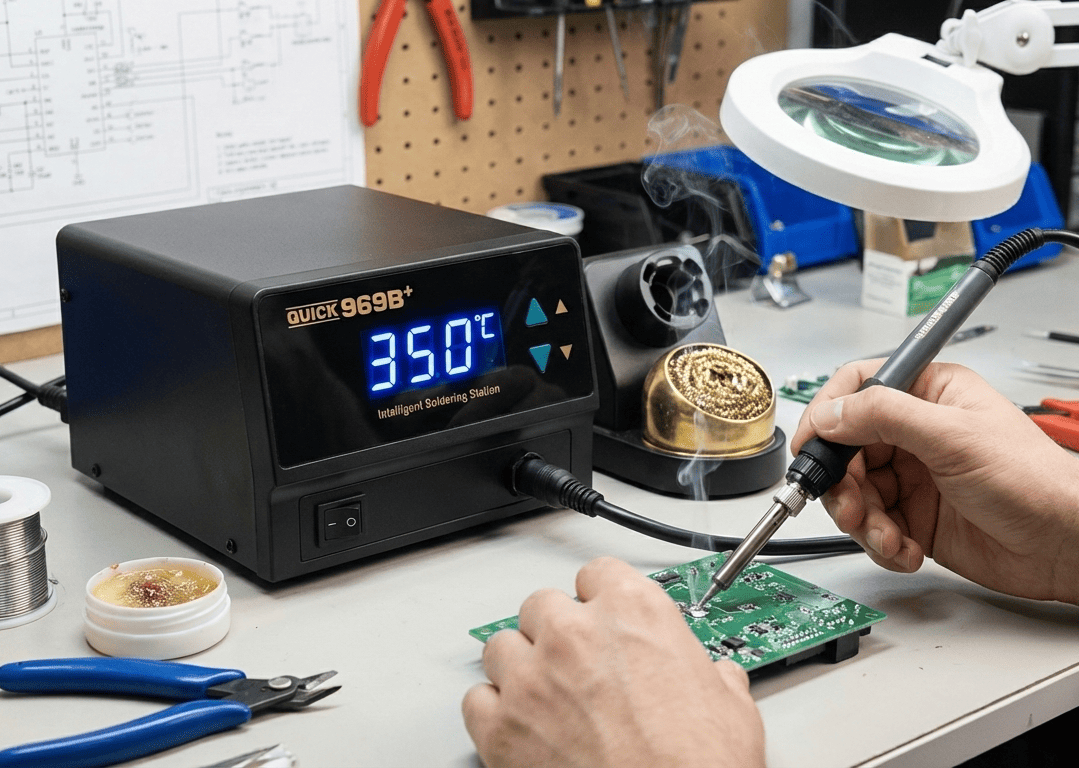

Digital soldering stations

Digital soldering stations are equipped with temperature display screens. Users can set suitable temperature levels for different types of components. Heat is maintained evenly throughout operation, resulting in clean solder joints and reduced risk of component overheating.

This type is suitable for professional technicians, component assembly workshops, and technical training laboratories.

Suggested soldering station brands

On the market, Quick and Atten are two soldering station brands widely used.

Quick soldering stations

Quick offers various digital soldering station models with compact designs and easy handling. These models feature fast heating, stable heat retention, and simple operation. Quick soldering stations are suitable for repair technicians and assembly workshops.

Atten soldering stations

Atten provides a diverse range of soldering stations, from basic models to high frequency digital types, capable of fast heating and maintaining even heat during continuous operation.

Atten soldering stations are commonly used for electronic repair, training, and component manufacturing due to their wide range of power options and price levels.

How to choose a soldering station based on usage needs

Selecting a soldering station should be based on working frequency and the type of components being handled.

1. Soldering stations for personal use and basic repair

Individual users or small repair technicians should choose soldering stations with power output around 60W to 75W. A temperature range from 200 to 480 degrees Celsius meets common component soldering needs.

Lightweight soldering handles, easy tip replacement, and fast heating should be prioritized for convenient operation.

2. Soldering stations for production workshops and professional repair

Assembly and maintenance workshops should choose soldering stations with power output from 90W to 150W. A wide temperature range allows handling of various component types.

Digital soldering stations with stable heat retention, anti static soldering handles, and effective heat dissipation designs are suitable for continuous working environments.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-