What is the cause of electrical overload? How to check most accurately?

When the electrical system is exploited beyond its load capacity, the risk is not simply a sudden power outage but can also lead to fire, damage to equipment and directly affect the safety of users. The worrying thing is that this situation often occurs silently, with little attention until the consequences appear. Therefore, this article will help you see more clearly about the phenomenon of electrical overload, the reasons why it occurs and how to check it properly so that the system is always operated in a stable and safe state.

Contents

What is an electrical overload?

An electrical overload occurs when the current flowing through a system exceeds the capacity that the system can handle. A common cause is the simultaneous use of multiple devices, which causes the total power consumption to exceed the design limit. In such cases, the circuit breaker (CB) – an overload protection device – will automatically disconnect the circuit to prevent wire fires, short circuits, or damage to connected equipment. This is a common issue in factories, offices, or households if load control is not properly managed.

Consequences of electrical overload

Electrical overload can cause many serious effects on the electrical system and equipment in use, including:

- Electrical equipment operates erratically or is damaged due to the system not providing enough electricity, causing interruptions during use.

- Equipment life is reduced rapidly because components are subjected to great pressure for a long time, leading to early deterioration.

- Electricity costs may increase because when overload occurs, consumed energy is lost or distributed inefficiently.

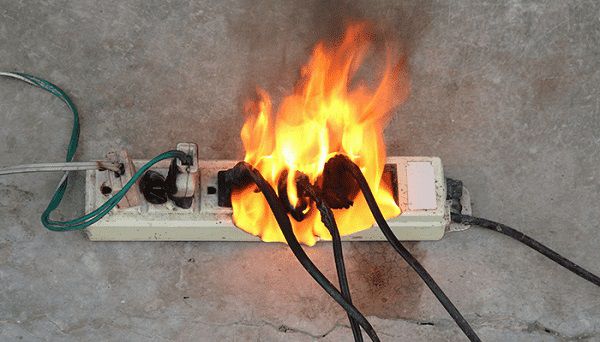

- The risk of fire and explosion is higher if the wire is overheated or the equipment is short-circuited due to being used beyond the allowable load.

- The power system is suddenly interrupted when the CB automatically cuts off the circuit to protect the equipment, causing a short-term local power outage.

- Continuously using excess electricity also contributes to putting pressure on the general power source, indirectly affecting the environment.

Causes of electrical overload

There are many reasons why the electrical system is overloaded, some of the most common ones are:

1. Using one outlet for too many devices at the same time

This is a common situation in homes or offices when too many devices are plugged into a single outlet. A normal outlet can only handle a maximum of about 3000W, but when users plug in a heater, rice cooker, electric stove or hair dryer at the same time, the total power exceeds the allowable limit. This increases the risk of overload, especially if used for a long time.

2. The wire does not meet the needs of use

The cross-section of the wire is a factor that determines the ability to transmit electricity. If you use a thin wire while using many devices with high capacity, the current passing through will cause the wire to heat up quickly. As a result, the insulation layer can melt, leading to short circuits or sudden power outages in the system.

3. The circuit breaker is not compatible with the load used

The circuit breaker is a protective device when there is an overload or short circuit, but if you choose a type with a capacity that is too small compared to actual use, the circuit breaker will often trip. This is not only annoying but also affects the durability of the electrical equipment due to sudden interruptions too many times.

4. Faulty or damaged electrical equipment

When the equipment has problems such as broken wires, short circuits, damaged sockets or damaged internal components, the current can increase abnormally and cause overload. If not detected early, these errors can burn the motor, damage the circuit board and create safety risks for the user.

The Most Accurate Way to Check for Electrical Overload

To check for electrical overload, the first priority is ensuring personal safety. Experts recommend contacting a qualified technician to inspect the electrical system.

However, you can still perform some basic checks yourself to preliminarily assess potential overload in your system.

1. Checking for Electrical Overload in Buildings and Construction Sites

Regular inspections in buildings are necessary to ensure safety and detect early signs of electrical overload. Some common steps include:

- Checking the rated power of electrical devices: Look at the maximum power rating of each device, usually found on its label or in the manual.

- Checking voltage and current: Use specialized measuring tools to verify whether current and voltage exceed permissible limits.

- Checking circuit breakers and CBs: Ensure that circuit breakers are still functioning properly, rated correctly, and have not lost sensitivity over time.

- Checking wire gauge: Compare the wire size with the power requirements of connected devices. Wires that are too small can lead to overload.

- Checking power factor: Evaluate the efficiency of power usage to determine if the system suffers from excessive losses.

- Performing in-depth testing if needed: If the system shows signs of instability or irregularities, conduct more advanced testing like power quality analysis or load response.

2. Checking for Electrical Overload in Manufacturing Plants and Substations

In factories or substations, inspections are usually carried out periodically by highly trained technical personnel. The inspection steps include:

- Determining the rated capacity of the system and electrical equipment: Understanding the maximum load capacity helps assess operational safety.

- Identifying factors affecting overload: Consider the number of active devices, circuit design, wiring, and load distribution.

- Checking the system and devices: Measure voltage and current, and assess devices for overheating, short circuits, or abnormal current levels.

- Checking circuit breakers and CBs: Ensure timely disconnection in case of overload or short circuit.

- Adjusting or upgrading the system if needed: If potential overload is found, technicians may recommend using larger wires, upgrading devices, or increasing CB sensitivity.

3. How to Check for Electrical Overload Using a Clamp Meter

You can quickly check the load current with a clamp meter using the following steps:

Step 1: Power on the clamp meter

Step 2: Switch to the power measurement mode (W symbol)

Step 3: Open the clamp and clamp it around the wire to be measured

Step 4: Read the value shown on the screen

Step 5: Compare it to the maximum power capacity of the system

Example: If your system operates at 200V and 15A, the maximum load is about 3300W. If the clamp meter shows a higher value, the system is overloaded, posing risks of short circuits or electrical faults.

How to Prevent Electrical Overload

To minimize the risk of overload and ensure a stable, safe electrical system, take proactive measures as follows:

1. Regular Inspection and Maintenance

Regularly checking the entire electrical system helps identify damage, degraded wires, or devices operating outside their specs. Periodic maintenance, such as cleaning electrical cabinets or tightening connectors, extends system lifespan and reduces overload risk.

2. Use Devices Within Rated Capacity

Avoid plugging too many devices into one outlet or using equipment beyond its rated capacity. Each device has a safe operating limit; exceeding it heats up wires and increases the risk of fire.

3. Choose Proper Wire Size and Install According to Standards

Wires must match the actual load. Undersized wires lead to overheating and fire risk. Installation must follow current technical standards for safety.

4. Install Protective Devices Like Circuit Breakers and Automatic Switches

Devices such as CBs, MCBs, or MCCBs cut power when overload or short circuit occurs, protecting both equipment and people. Choose breakers with appropriate cut-off current for your system.

5. Monitor Power Consumption with Sensors and Measuring Devices

Use modern tools like clamp meters, current sensors, or smart monitoring systems to track real-time energy usage. This is especially useful in factories or large buildings.

6. Follow Industry Standards and Electrical Codes

System design and operation must adhere to technical standards (TCVN, IEC...) and electrical safety regulations. Proper compliance from the start helps prevent future incidents.

7. Raise Awareness and Train Personnel

Technicians and operators should be well-trained in electrical safety, troubleshooting, and overload prevention. Human error is a major risk factor that can be reduced through training.

8. Develop Emergency Response Plans

Have a contingency plan in place for incidents like fire, short circuit, or overload. This should include wiring diagrams, procedures, responsible personnel, and emergency handling tools.