How to calculate and choose the right hydraulic pump for the system

Hydraulic pumps operate based on the rotary motion provided by an electric motor or diesel engine. When operating, it has the task of sucking liquid such as oil or lubricant and pushing it continuously through the system, ensuring the entire circuit operates smoothly. Therefore, this device plays a key role in any hydraulic system.

Contents

Calculating and selecting the right hydraulic pump is not easy, especially for those who do not have much experience. If you are wondering how to determine the parameters to choose the right pump, please refer to the article below. Specific instructions will help you more easily calculate and choose the pump that meets the technical requirements.

Overview of hydraulic pumps in the system

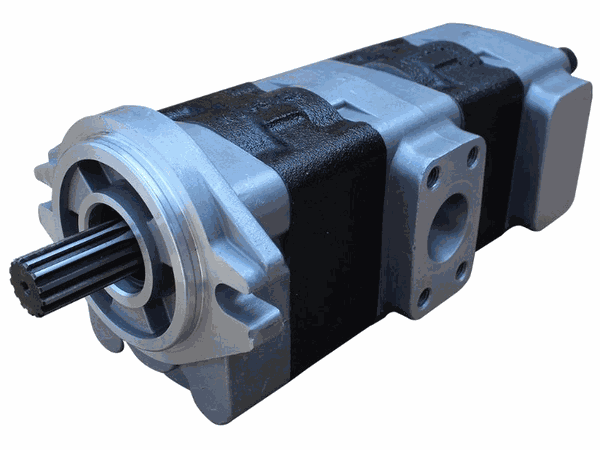

Hydraulic pump, also known in English as Hydraulic Pump, is one of the core components of the hydraulic transmission system, along with devices such as valves, cylinders, oil tanks or filters. The main task of the pump is to create a pressurized oil flow, bringing oil from the tank to the actuators so that the system can operate continuously. Normally, the pump will be installed near the tank to ensure the most effective oil suction and discharge. After being sucked up, the oil will follow the pipe through the control valves, to the one-way or two-way cylinders depending on the design. When the oil returns to the tank, the pump continues the next operating cycle, creating a closed loop.

Because of its central role, pump selection cannot be arbitrary. During design or maintenance, technicians need to calculate and select hydraulic pumps based on parameters suitable for the system. If selected incorrectly, the pump can work beyond its capacity, causing overheating, reduced efficiency or rapid damage.

See more: Configuration and operating principles of hydraulic pumps

Instructions on how to calculate and choose hydraulic pumps

In a hydraulic system, the pump is the device that determines whether or not it can generate enough force or torque for the actuators to operate effectively. If you choose the wrong type of pump or do not calculate carefully, the system may end up consuming unnecessary energy or not having enough capacity to operate.

The first step in calculating the choice of a hydraulic pump is to determine the type of pump you need to use. For example, when you need a large flow but not too high pressure, you can consider using a vane pump or a piston pump. In the case where the system requires high pressure but not much flow, a gear pump will be a worthy choice.

Next, you should also clarify whether you will use an electric or manual pump depending on the specific purpose and working environment.

Next is the most important step: calculating parameters such as capacity, working pressure and oil flow that the pump needs to provide. These data can be determined by technical formulas and compared with the parameters from the manufacturer.

How to calculate hydraulic pump flow

Flow is understood as the volume of oil that the pump can push in a certain period of time. The common units of flow are cubic meters per hour or liters per minute.

On each pump, you can see the specific flow index - this is the amount of oil the pump produces in one revolution. The common unit is cc per revolution.

To calculate the actual flow of the pump, you can use the following formula:

Q = q × n

Trong đó:

Q is the pump flow rate, usually in liters per minute or cubic meters per minute

q is the specific flow rate, in cc per revolution

n is the number of revolutions per minute of the pump drive motor

Hydraulic pump pressure

After determining the flow rate, the next factor you need to consider when calculating the selection of a hydraulic pump is the pump pressure. This is a parameter that represents the ability to generate force or torque for the hydraulic cylinders and motors in the system. To calculate the pressure required for the pump, you can use the formula:

P = F / S

In which:

F is the force that the system needs to generate to push the load, the unit is Newton

S is the cross-sectional area of the piston rod, the unit is square meter

P is the pressure generated, the original unit is Newton per square meter. However, in practice, people often convert to more common units such as bar or psi. Specifically, 1 bar is equivalent to 100,000 Newtons per square meter.

How to calculate pump capacity

Based on the two available parameters of flow and pressure, you can continue to determine the required capacity of the pump according to the formula below:

N = P × Q / 612

In which:

P is pressure, unit bar

Q is flow, unit liters per minute

N is the required capacity of the pump, unit kilowatt

An important note in the process of calculating and selecting a hydraulic pump is that the pump should not be operated at the limit continuously. To ensure durability and stable performance, you should choose a pump pressure higher than the actual calculated pressure. For high pressure systems, add about 10 percent. For systems requiring low or medium pressure, the reserve level should be between 20 and 30 percent. This helps avoid pressure drops or performance reduction after a long period of operation.