Learn about contactor auxiliary contacts and how they optimize electrical systems

In many electrical control systems, there are small components that have a significant impact on operating efficiency, and the contactor auxiliary contact is a typical example. Integrated to expand control capabilities and increase flexibility for the starter, the auxiliary contact not only helps monitor the status of the device but also effectively supports circuit protection functions. The following article will clarify more about the contactor auxiliary contact, let's take a look!

Contents

What is the definition of contactor auxiliary contact?

Auxiliary contacts are small components added to the contactor to help expand the control capabilities of related auxiliary circuits. In modern control systems, especially in manufacturing plants, automation lines or central electrical cabinets, the need to simultaneously control multiple operating states such as: indicator lights, cooling fans, relay warnings, or PLC signals is very common. Auxiliary contacts allow these tasks to be performed flexibly without interfering with the main circuit.

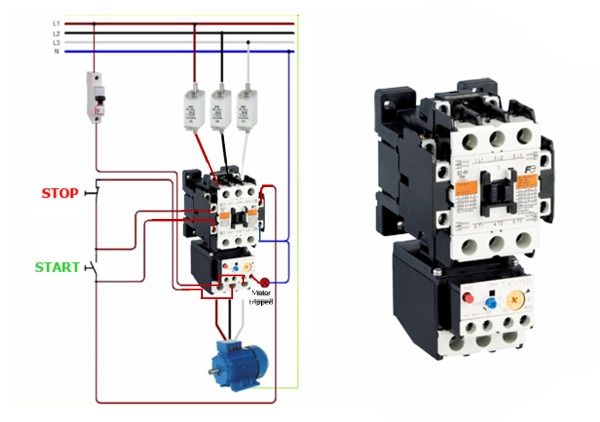

This component often works simultaneously with the contactor: when the contactor closes or opens, the auxiliary contact also changes its state accordingly to send control signals to other sub-circuits. Not only limited to contactors, auxiliary contacts are also integrated in circuit protection devices such as MCB, MCCB, or ACB to monitor and notify the on/off status of the device.

In terms of structure, the auxiliary contact is relatively simple with three main parts:

Contact: is a conductive contact point, including two main types: normally open (NO) and normally closed (NC).

Coil: generates a magnetic field when energized, helping to change the contact state.

Protective shell: covers the internal components and creates a structure for assembly with contactors or other devices.

Currently, there are two types of auxiliary contacts commonly used:

Normally Open (NO) Contact: In normal condition, the two contacts are not in contact with each other. When the contactor is activated, the NO contact closes and allows current to pass through. This type is often used to control indicator lights when the device starts to operate, to supply power to a timer or a cooling fan only when the motor is running. Normally Closed (NC) Contact: Always conducts electricity when not activated. When the contactor is energized and activated, the NC contact will disconnect. This type of contact is often used to interrupt the alarm when the device is operating or to close the protection circuit when the motor stops.

What is the function of auxiliary contacts in the control system?

When installed with a contactor, the auxiliary contact plays a supporting role but plays an important role in optimizing the overall control capability. Instead of having to arrange many separate devices, with just one contactor combined with an auxiliary contact, users can expand the control of many sub-circuits neatly and save space in the electrical cabinet.

Some common functions of auxiliary contacts in the control system:

Expanding the control area: Allows the activation of additional devices such as signal lights, alarms or counters when the contactor is operating.

Signaling to relays and logic circuits: Facilitates integration with automation systems, especially in production lines.

Device status monitoring: By providing feedback signals, the central controller knows whether the contactor is in an open or closed state.

Increased safety and load protection: When there is a problem in one branch, the auxiliary contact helps isolate the faulty circuit without affecting the rest.

For example: When the contactor closes and the NO auxiliary contact closes, the signal is transmitted to the IDEC RU4S-A220 intermediate relay to control the "motor running" indicator light or send a signal to the PLC, helping the automation system operate smoothly.

See more at: Control relay

Difference between auxiliary contact and main contact in contactor

Although they are both part of the contactor system, the main contact and the auxiliary contact have completely different functions.

The main contact is the part responsible for switching the main load current, usually a high-intensity current used to control motors, capacitor banks, generators or high-power consumption devices. It is designed to ensure durability and good conductivity when operating for a long time with a large load.

In contrast, auxiliary contacts usually only open/close small currents, enough to activate control circuits, signals or status indicators. This is an auxiliary component that does not directly affect the main load current but is very important in building an intelligent and safe control system.

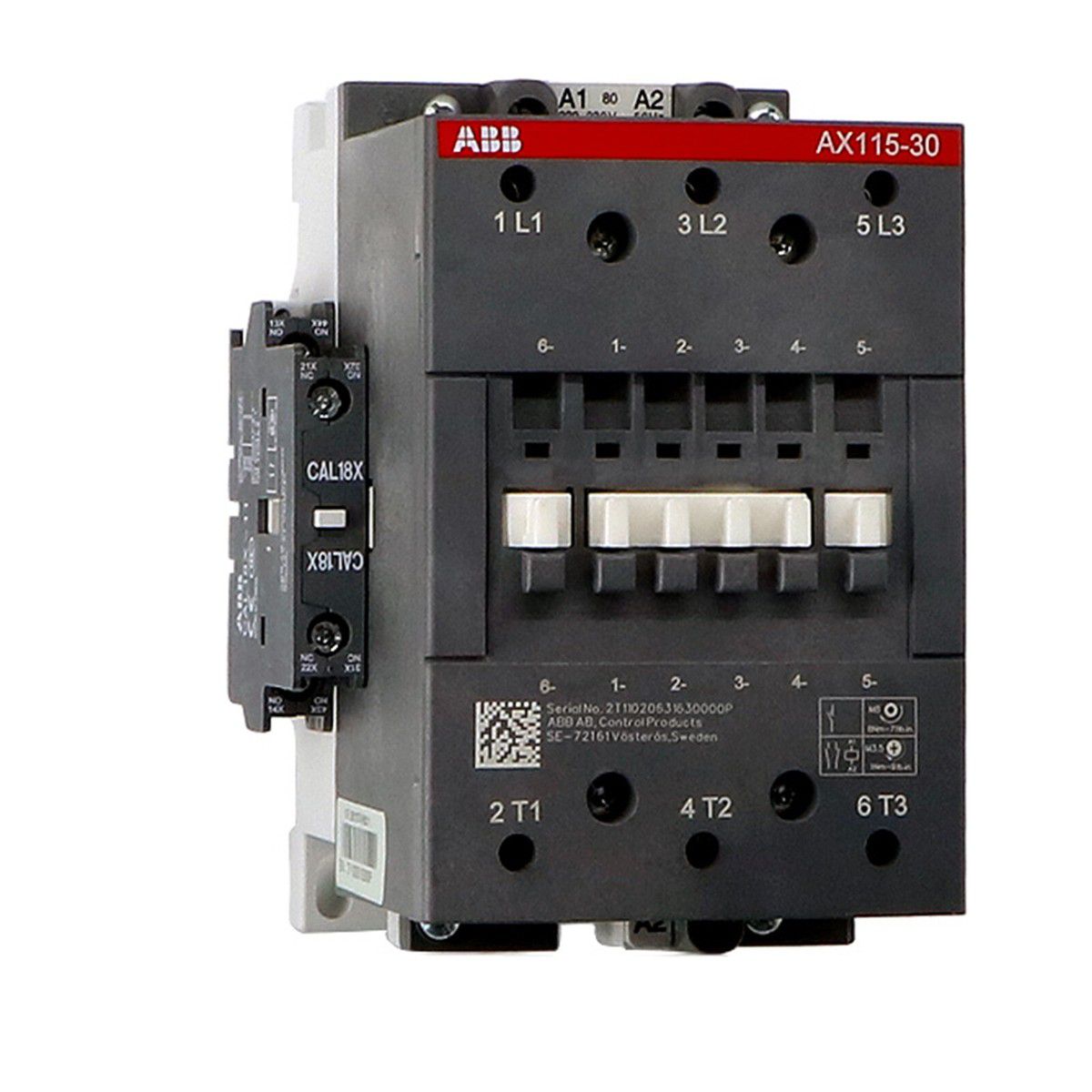

A notable difference: the main contact is a fixed part located in the contactor block, while the auxiliary contact is an optional accessory that can be installed outside or on the side of the contactor depending on usage needs.

Practical application of auxiliary contacts in electrical systems

Auxiliary contacts are commonly used in many modern switching systems, not only limited to contactors but also appearing in devices such as MCB, MCCB, or ACB - where it is necessary to expand control signals or provide status feedback. Thanks to its compact design and flexible compatibility, this component contributes to improving the accuracy and safety of the entire control system.

In industrial environments, auxiliary contacts are often integrated into electrical cabinets to control motors, conveyors, presses, or ventilation and heating systems. When the contactor is closed, the auxiliary contact will simultaneously transmit a signal to activate a cooling fan or an equipment status indicator light. Conversely, when the contactor is open, the signal from the auxiliary contact can be used to stop the system or send an alarm to the control center.

On a residential or commercial scale, auxiliary contacts help remotely control lighting systems or household appliances, and also act as an intermediary to transmit safety signals when the system encounters problems such as overload or short circuit.

In terms of specific functions, normally open (NO) contacts are suitable for applications that require the device to operate only when the contactor is activated, such as a warning light that only illuminates when the motor is running. Meanwhile, normally closed (NC) contacts are selected to disconnect the signal when the device starts, such as stopping a pump when there is a problem or when the system is no longer in standby mode.

Experience in choosing suitable auxiliary contacts for each type of contactor

In order for the auxiliary contact to operate stably and synchronously with the contactor, it is necessary to carefully consider factors related to technical parameters and operating conditions. One of the first important points is compatibility. The auxiliary contact must be suitable for the rated current and operating voltage of the contactor, both in terms of technical parameters and mechanical connection type.

In addition, in many working environments such as factories, mechanical workshops or transformer stations, where there is high humidity, dust or constantly changing temperatures, choosing the type of auxiliary contact that can withstand environmental conditions well is very necessary to avoid technical errors during operation.

Another factor that is often overlooked is the contact response time. In some automation systems, the response time of the control signal is very important. Selecting auxiliary contacts with a closing/opening speed that matches the requirements of the control cycle will help to limit signal delay or pulse noise in the system.

Suggested suitable products:

Contactor series with built-in auxiliary contacts: Contactor ABB AX205-30-11-80: Available with 1 NO + 1 NC contact, suitable for systems requiring basic control and feedback.

For systems requiring multi-level control or equipment status monitoring, it is recommended to use a contactor supporting auxiliary contacts such as the ABB AX205‑30‑11‑80 model, which has 1 normally open and 1 normally closed contact built-in. This helps reduce costs and installation time when no additional accessory modules are required.

Conclude:

With the ability to expand control, increase flexibility and ensure safety in operation, auxiliary contacts increasingly affirm their important role in industrial and civil electrical systems. From contactors to devices such as ACB or MCCB, this small component helps optimize the control process without changing the main circuit structure. Choosing the right type of auxiliary contact not only helps the device operate stably but also prolongs the life of the entire system.