Optical analyzer

Why Does Material Production Require Optical Analyzers?

The material manufacturing sector has always been a key industry serving the ever-increasing demand for industrial fabrication, construction, and electronics. Ensuring material quality is a crucial factor in helping final products meet international standards and compete in the market. Optical Analyzers play a supporting role in measuring, inspecting, and storing complex 3D data of the materials.

How Do Optical Analyzers Help Engineers Inspect and Store 3D Material Data?

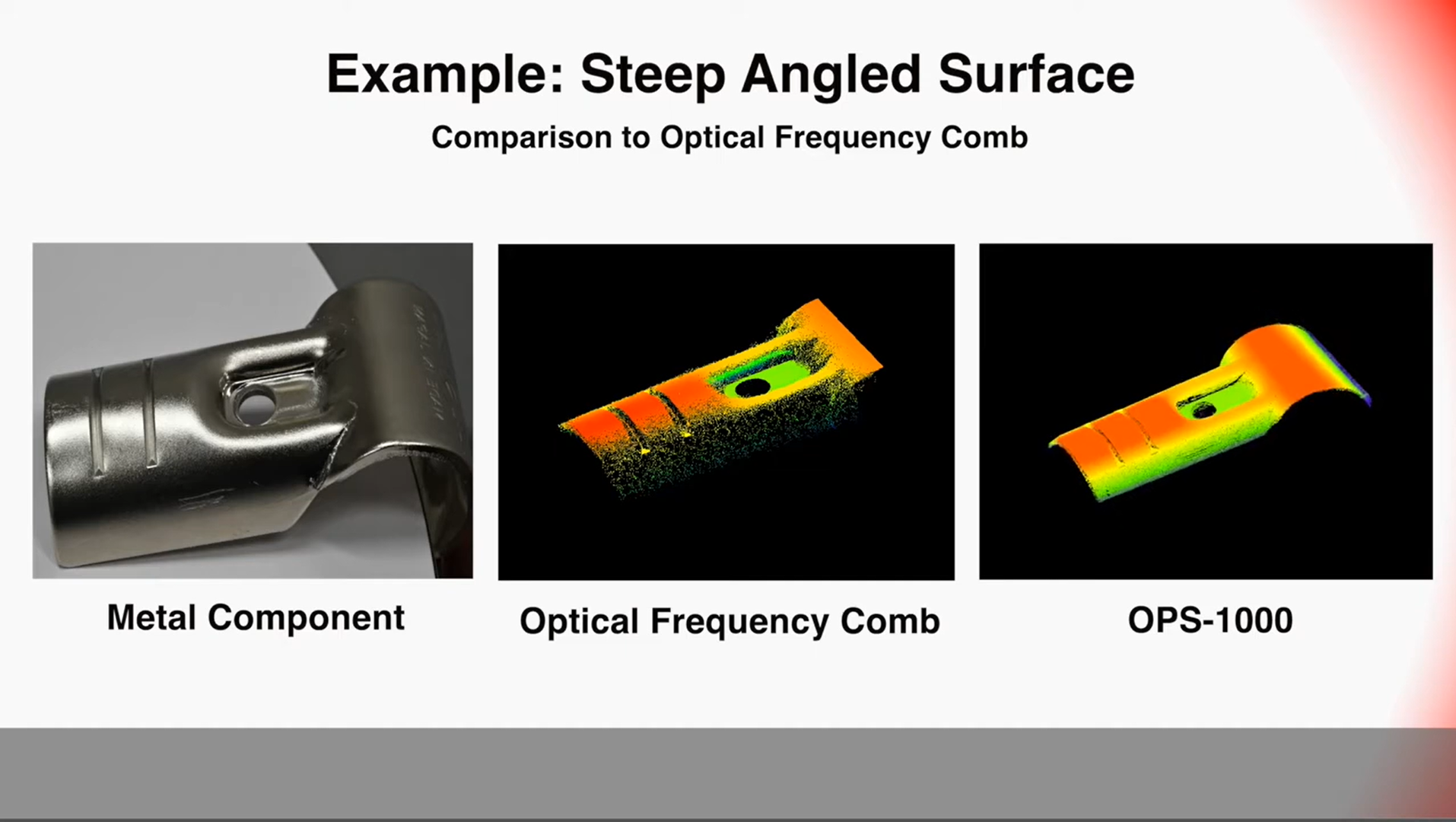

Optical analyzers use optical scanning technology to collect material surface data in the form of high-resolution 3D point clouds. This provides engineers with a comprehensive and detailed view of the material's structure, roughness, cracks, or minor defects that are invisible to the naked eye.

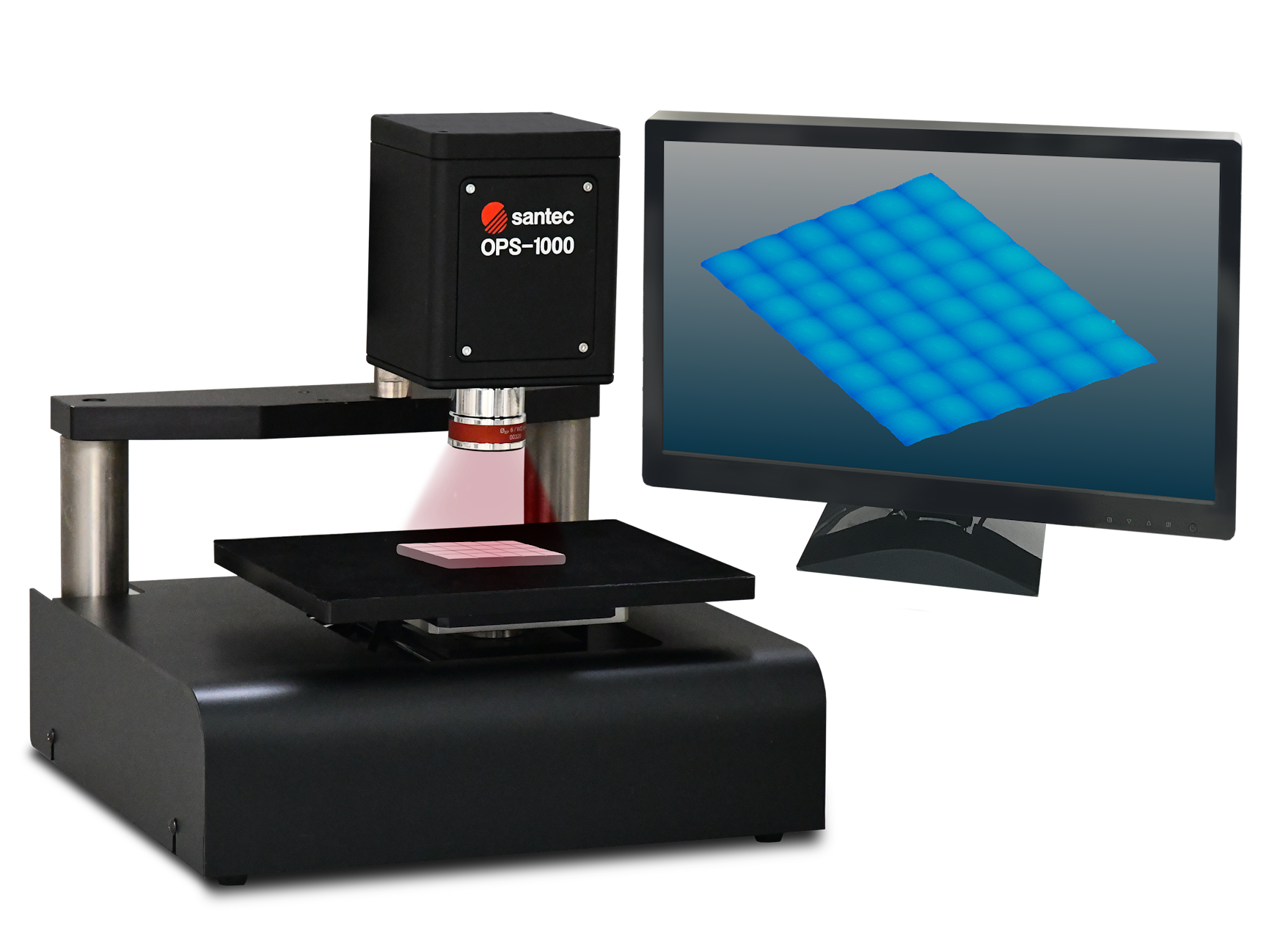

For example, the High-resolution Optical Analyzer Santec OPS-1000 stands out with light detection sensitivity up to 100dB and a fast measurement speed of 400,000 points per second. The device features automatic data storage and processing, allowing engineers to easily monitor surface changes in real-time. Quality control and production adjustments are thereby based on the most accurate and complete data available.

How Optical Analyzers Work in Material Production

The operating principle of an optical analyzer is based on emitting a beam of light at a fixed wavelength and then receiving the reflected or interfered light from the material sample surface. Sensors and lens systems convert the light signal into digital data, reconstructing it into an image or a 3D point cloud representing the material surface.

The key difference lies in the sensitivity and resolution of the receiver head and the processing speed, enabling the device to detect details down to micrometers or even nanometers. In the Santec OPS-1000, new interferometric technology allows for the elimination of environmental light interference, maintaining measurement accuracy even under real-world factory conditions.

The results obtained are analyzed by the accompanying software, compared against acceptable standards, and detailed reports are provided, enabling engineers or production managers to make immediate adjustments, thereby increasing quality control efficiency.

What Criteria Should Be Prioritized When Choosing an Optical Analyzer?

When selecting an optical analyzer for metal production, you need to focus on:

High accuracy in detecting elemental composition, especially light elements.

Fast analysis speed to avoid interrupting the production line.

The ability to analyze multiple elements simultaneously.

Low operating cost through minimal energy and supply consumption.

Easy-to-use support software and automatic standardization/calibration.

These criteria help you ensure effective metal quality control, enhance productivity, and meet technical standards in modern manufacturing.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-