Air Sander

Should You Switch to an Air Sander for Your Workshop?

What is an air sander? This is a question that any long-time carpenter or production workshop owner looking for improvement is concerned about. Is switching from an electric to an air-powered machine truly worthwhile? Let's delve into the excellent advantages of this machine line with EMIN.

What is an Air Sander and How Does It Work?

Air sanders often appear where the sound of machinery runs non-stop: carpentry shops, furniture workshops, metal fabrication areas, or auto garages. This tool helps workers save time on grinding, sanding, and smoothing surfaces every day.

Core Concept

Completely different from the electric version, the Air Sander operates using the pressure of compressed air supplied from an air compressor.

Precisely because it does not use direct electricity, the air-powered machine becomes a much safer choice than the electric version, eliminating the risk of short circuits and fire or explosion. This is particularly crucial in working environments with many flammable materials and solvents, such as paint shops or woodworking shops.

Related Articles:

The role of sanding machines in manufacturing and daily life

Do not rush to use a sanding machine if you haven't grasped these things

Simple Operating Principle

The machine's operating principle is quite intuitive: Compressed air enters the motor, converting into mechanical energy, which creates the rotation or oscillation for the sanding pad.

Motion: With orbital machine lines, the sanding pad not only rotates but also oscillates along an eccentric orbit. This specifically helps increase the speed of sanding and simultaneously minimizes the swirl marks often found on material surfaces.

Structure: The machine is designed to be compact and easy to grip. Components like the air shut-off valve and the trigger are optimized so that the worker can easily control the airflow, adjust the speed, and quickly start/stop the machine.

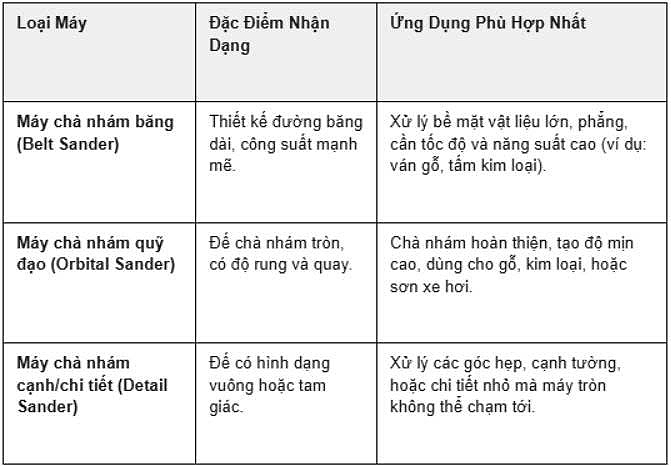

How to Choose the Most Suitable Machine Type?

There are many types of air sanders on the market, designed to address specific production issues:

Why is it said that the Air Sander can, at times, outperform the electric sander?

It can be said that this is a lucrative investment with a reasonable price that brings long-term benefits to professional production workshops. For the following reasons:

Can "Work Continuously" with No Overheating Worries

This is the biggest advantage, especially important for workshops working long shifts. The air-powered machine does not use electric coils like an electric motor; therefore, it generates almost no heat when running. This means the machine can operate continuously and reliably without worrying about overload, overheating, or motor burnout, which helps speed up work progress.

Enhanced Safety

As mentioned, not using direct electricity is a major advantage of the air sander. In woodworking or paint shops with fine dust and easily flammable solvent fumes, completely eliminating the risk of electrical sparks from the electric sander helps protect assets and the lives of the workers.

Most Compact Size, Easy to Operate

Air sanders are typically designed to be extremely compact and lightweight, minimizing hand fatigue when having to operate continuously or work in difficult positions such as overhead or in tight corners. This helps the worker easily control the sanding force, resulting in a more uniform and higher-quality finished surface.

When Should You Invest in an Air Sander?

This will be the perfect choice for the following:

Large-scale production workshops (Wood, Furniture, Mechanical, Automotive): Where high productivity, continuous operation, and high intensity are required.

Facilities that already have a compressed air system: Allowing them to utilize existing infrastructure and optimize costs.

Businesses that prioritize finishing quality: Air sanders allow for better control, resulting in a higher degree of smoothness.

Reference Hot Air Sander Models Available at EMIN

Currently, EMIN offers a wide selection of high-quality air sanders, suitable for every need. Customers can refer to popular models such as the high-performance orbital line Random Orbital Sander AIRTEC 533/10 B (Pad 150 mm; Orbit 10mm)orbital line Random Orbital Sander AIRTEC 533/10 B (Pad 150 mm; Orbit 10mm), the powerful specialized machine Air Sander 02525 (5", 11000Rpm), and the high-power, durable line Self-Vacuum Sander KAWASAKI KPT-1105DS. Click on the product name to see detailed specifications and place your order today!

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-