What are the ways to determine the dew point temperature of compressed air?

Why does compressed air need humidity control? And why is dew point temperature such a concern? If you are working with compressed air systems, this is a concept you should definitely understand.

Contents

Concept of Dew Point Temperature

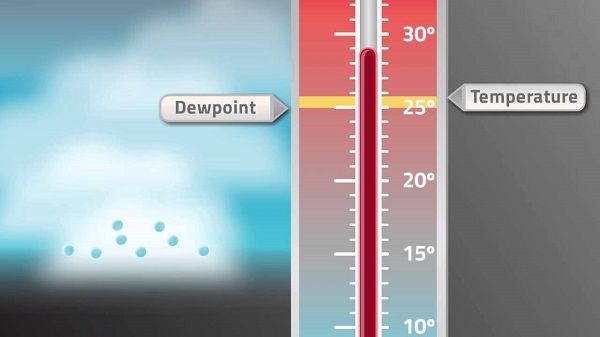

Dew point temperature is the temperature at which water vapor in the air begins to condense into liquid form. When air is cooled to this threshold, humidity reaches 100% saturation and can no longer retain additional moisture.

The dew point value changes with humidity levels. The more humid the air, the lower the temperature must be reduced to reach the dew point. In practice, the dew point is usually lower than the surrounding air temperature.

For example, when the air temperature is 25°C with 70% humidity, the dew point is approximately 19°C.

Dew Point Temperature in Compressed Air

In compressed air systems, the dew point temperature refers to the temperature at which water vapor starts to condense into liquid form. This value is influenced by the pressure and initial humidity of the air. When air is compressed, the pressure increases, affecting the temperature. However, if the humidity remains unchanged, the dew point does not vary significantly.

Compared to ambient air, compressed air typically contains more water vapor, resulting in a higher dew point. When compressed air is cooled before use, the vapor easily condenses, forming droplets or mist that can disrupt equipment operation and damage the system.

Because each compressed air system has different operating conditions and air composition, there is no fixed standard for the dew point. It varies depending on pressure, humidity, and the air treatment process.

Significance of Dew Point Measurement

Dew point temperature is an important indicator used to determine how dry compressed air is after passing through an air dryer. This allows operators to evaluate whether the air meets the usage requirements for equipment and make appropriate adjustments based on specific needs.

Using a Dew Point Meter

A dew point meter is used in many compressed air systems to check the temperature at which water vapor begins to condense. It operates by cooling a surface and identifying the moment moisture condenses into droplets, which indicates the dew point temperature.

Modern devices typically feature clear digital displays. Some models support data logging or data transmission, making long-term monitoring easier and improving control over air quality.

Examples of Dew Point Meters Available at EMIN:

Wöhler TI 410 Dew Point Meter (-40 to 100°C)

PCE DPM 3 Temperature, Humidity, and Dew Point Meter

Shaw SDHmini-Ex Handheld Dew Point Meter

Factors Affecting Dew Point Measurement

Dew point temperature is influenced by several factors. Initial humidity is the most important—higher humidity leads to a higher dew point. Air temperature also plays a significant role; the lower the air temperature, the lower the dew point. Air pressure also affects dew point but has a limited impact under normal conditions. Based on these factors, systems can be adjusted to maintain a dew point that aligns with actual operational needs.